Description

Patsari is a wood-saving stove which was developed in Mexico by the organisation GIRA (Interdisciplinary Group of Rural-Appropriate Technology) during the 2000s. Easy to build, low-cost and safe with regards to its impact on human health, the Patsari has since been rolled out to many different rural communities across Mexico.

Sommaire

Sommaire

[masquer]- 1 Description

- 2 Sommaire

- 3 Introduction

- 4 Video d'introduction

- 5 Étape 1 - Construction Plans

- 6 Étape 2 - Stove Base

- 7 Étape 3 - Formwork Construction

- 8 Étape 4 - Implementing Mortar

- 9 Étape 5 - Building the Edges of the Stove

- 10 Étape 6 - Constructing the Combustion Chamber

- 11 Étape 7 - Filling the Base

- 12 Étape 8 - Positioning the First Hotplate and Smoke Venting Tunnels

- 13 Étape 9 - Positioning the Secondary Hotplates

- 14 Étape 10 - Filling the Cooker

- 15 Étape 11 - Smoke Venting Passage

- 16 Étape 12 - Installing the Hotplates

- 17 Étape 13 - Finishing Touches and Installing the Chimney

- 18 Étape 14 - Recommendations for Use

- 19 Notes et références

- 20 Commentaires

Introduction

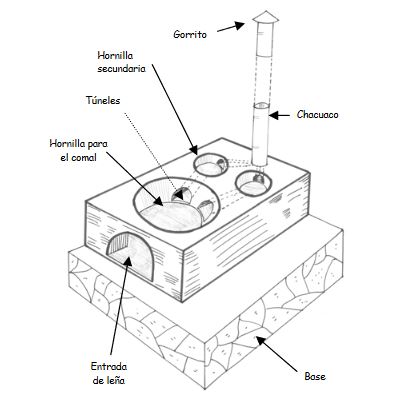

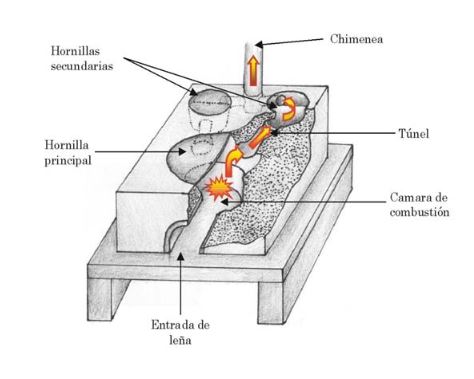

The Patsari stove adapted and improved upon the Lorena model which was developed in Guatemala and Mexico in the 1980s. It was designed and distributed by the Grupo Interdisciplinario de Tecnología Rural Apropriada (GIRA) located in Patzcuaro, Michoacan, Mexico. During 20 years of fieldwork in collaboration with users of the Lorena design, several improvements have been incorporated into the Patsari model:

- To increase its lifespan, the exterior is made of brick

- For better standardization, the construction process uses molds to ensure the correct dimensions of the combustion chamber

- An optimized combustion chamber

- Secondary burners that maximize heat transfer to multiple cooking surfaces

- Chicanes redirect the hot gases to the secondary burners.

- The hotplates (comals) are sealed to prevent smoke from entering the room.

- A prefabricated chimney base for easier cleaning

In the Purhe'pecha indigenous peoples' language, Patsari means "the one who takes care of;" the stove is designed to take care of the health of the users as well as the overall environment. The main advantages of this cooker are:

- 50% reduction in fuel consumption compared to an open fire.

- 66% reduction in the concentration of particles and toxic gases (CO) in indoor air compared to an open fire.

- Reduced eye irritation and respiratory illness from cooking fumes.

- Saves time and money; because less wood is consumed, less time is spent collecting wood and less money is spent purchasing it.

- Built with local materials, soil and sand.

- Easily adaptable, simple-to-use on a daily basis.

Youtube

Matériaux

-

Outils

-

Étape 2 - Stove Base

Before constructing the Patsari stove, you need a solid, stable base, not only for greater comfort for the user, but also for the sake of safety around children and pets. In general, the base measures 1m wide by 1.20m long and 60cm high; these measurements ensure sufficient space for placing kitchen utensils, for example.

Construction Materials

The base can be constucted with available household materials or other materials that are easily affordable. Some examples of potential materials are:

- adobe

- concrete

- brick

- metal

These bases can be filled in completely or hollow. The hollow base has more advantages, because it can be used to store and dry wood, or for storing dishes.

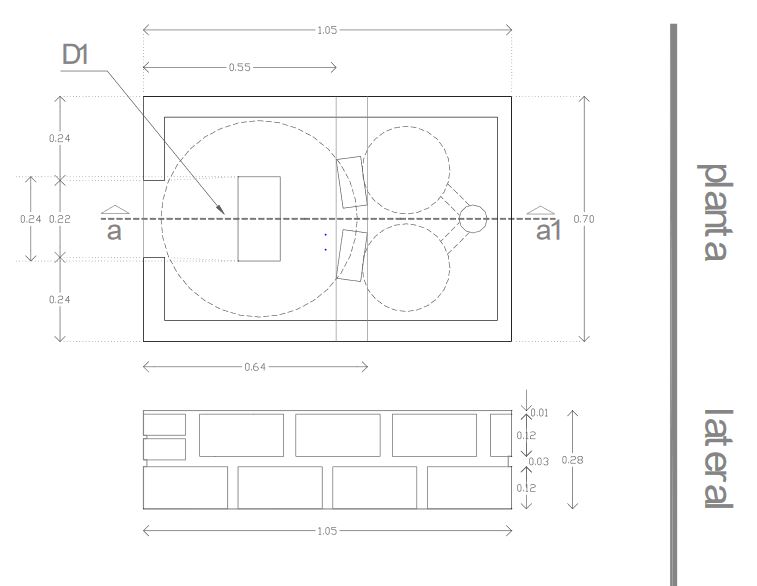

Étape 3 - Formwork Construction

- On the base, a form is made in which to pour the mixture. This mold will be made of four wooden planks (covered with form release oil) or metal sheets with four metal bars for adjustment.

- Recommended dimensions: 80cm x 100cm x 27.5cm

If the stove is to be built in a corner of the house or near a wall, leave a gap (about 5cm) for the pieces of the formwork to be removed.

Étape 4 - Implementing Mortar

- Implementing the basic mortar:

- Mix 3 buckets of commercial grade sand (20L) + 1 bucket of cement (Multibat type)

- Mix well with a shovel

- Slowly add 5 to 10 liters of water while mixing continuously

This mixture will be used to bond the bricks.

2. Making the clay mortar

- Mix 2 buckets of commercial grade sand + 1.5 buckets of soil (sifted finely)

- Stir well until mixture is a uniform color.

- Add 3-4 scoops of mortar.

- Add 5-10 liters of water, pouring little by little into the mixture. It is recommended to stir the mixture, so that it is evenly moist, until it reaches a sticky consistency. To see if the mixture has the right amount of moisture, take a handful and see if it runs off your hand; if not, it is ready to use.

This mixture will be used for filling the interior of the cooker.

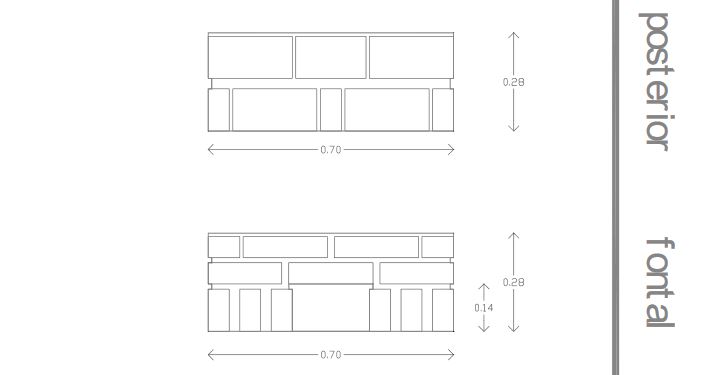

Étape 5 - Building the Edges of the Stove

- Dip the bricks in a bucket of water and assemble them with mortar according to the plans above. The recommended thickness of mortar is usually 2cm.

- Split some bricks as needed to adapt them to the correct dimensions.

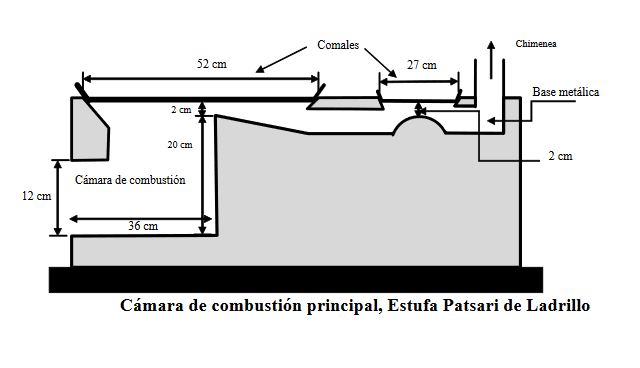

Étape 6 - Constructing the Combustion Chamber

- Dip the bricks in a bucket of water and assemble them with mortar according to the plans above. The recommended thickness of mortar is usually 2cm.

- On the last row, break 1 brick in half lengthwise to create a border that will wedge the "comal" (hotplate) in place.

Étape 7 - Filling the Base

- Fill the space around the combustion chamber with gravel to a level height.

- At the end of the stove, position the "chacuaco" (smoke venting piece)

- Cover the gravel with a thin layer of sand to fill in the gaps. Smooth it over.

Étape 8 - Positioning the First Hotplate and Smoke Venting Tunnels

- Position the large hotplate. Make sure it is in the center of the stove.

- Position two hollow bricks, two sections of aluminum, or two tin cans (note that tin cans risk oxidizing quite quickly), against the hotplate at the exit of the combustion chamber so as to form two smoke venting tunnels. Make sure to leave a height of 2cm between the top of the tunnel and the edges of the cooker.

Étape 9 - Positioning the Secondary Hotplates

- Pour two buckets of soil mortar at the location of the secondary hotplates.

- Insert the molds at the hotplate sites. You could use two plastic bowls of the same diameter as the hotplates + two pieces of wood instead of molds.

- Make sure the hotplates are level with the edges of the stove.

Étape 10 - Filling the Cooker

- Fill the empty space with soil mortar up to the height of the oven edges. Leave empty spaces at the combustion chamber and inside the molded space for the secondary burners. Also take care not to obstruct the chimney flue.

- Mark the exact measurements of the 3 hotplates and cut the outline using a masonry trowel.

- Be careful not to obstruct the combustion chamber.

Étape 11 - Smoke Venting Passage

- Use a trowel to dig a passage in the mortar for free access to the smoke venting tunnels and create a circuit between the combustion chamber and the two secondary hotplates.

- Make sure to leave a 2cm tall passage between the hotplate and the dent created in the secondary chambers.

- Dig a passage between the secondary chambers and the base of the chimney flue.

Étape 13 - Finishing Touches and Installing the Chimney

- Create a nice, smooth surface by moistening it a little and smoothing with the trowel.

- Carefully remove the formwork around the cooker.

- If necessary, scrape down and smooth the edges of the cooker for a better finish.

- Insert the tubes in the smoke venting ducts to form the chimney flue.

- The stove takes about a week to dry completely.

Étape 14 - Recommendations for Use

- Distribute the wood evenly at the entrance of the combustion chamber for a more even temperature under the main hotplate.

About once a week:

- Clean the ash from the combustion chamber.

- Clean the smoke venting tunnels.

- Clean the chimney flue.

Notes et références

- Estufa Patsari Construction Manual in Spanish: http://www.stoves.bioenergylists.org/files/ManualPatsari.pdf

- Helpful video tutorials for construction: https://www.youtube.com/watch?v=ecqqWO5hqKs and https://www.youtube.com/watch?v=MohCoH5ODkI

- Construction plans for the Estufa Patsari: http://bioenergylists.org/files/NuevaEstufaPatsari_GIRA.pdf

- Estufa Patsari performance study (Spanish): http://ecotec.cieco.unam.mx/Ecotec/wp-content/uploads/From-cookstoves-to-cooking-systems.-The-integrated-program-on-sustainable-household-energy-use-in-Mexico.pdf

- Construction tutorial for the Estufa Lorena (old model) in Spanish: https://www.crim.unam.mx/patrimoniobiocultural/sites/default/files/PL6.pdf

- Study on the improvement of the Estufa Lorena to the Estufa Patsari: http://www.bioenergylists.org/estufasdoc/Rodolfo_Diaz/DeLorena-a-Patsari.pdf

- English translation by Bailey Bishop & Simon Conheady

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português