Description

The biosand filter is a household water filter that makes dirty water drinkable.

Sommaire

Sommaire

[masquer]- 1 Description

- 2 Sommaire

- 3 Introduction

- 4 Video d'introduction

- 5 Étape 1 - How does the biosand filter work?

- 6 Étape 2 - OHorizons Wooden Mold Construction Manual

- 7 Étape 3 - Concrete Filter Construction Manual

- 8 Étape 4 - Video Series on the Construction of the Bio-Sand Filter

- 9 Étape 5 - Frequently Asked Questions

- 10 Commentaires

Introduction

This document will help you understand the fundamental principles of the biosand filter (FBS): how it works, the different elements and why it might be a good technology for your project. If you have other questions that this document doesn’t answer, don’t hesitate to contact us (info@ohorizons.org).

The biosand filter (FBS) was invented in the 1990s by Dr. David Manz at the University of Calgary. Simply put, the FBS is a domestic water filter that makes dirty water safe to drink. This particular type of filter is an adaptation of the traditional slow sand filter used for community water treatment for almost 200 years.

The FBS is smaller and adapted for intermittent use, which makes it the most appropriate for households of around 5 people. The filter body, or the exterior of the filter, both known under the name of filter housing, are commonly made of concrete, but can also be made of plastic. Regardless of the type of filter housing, an FBS is filled with carefully prepared layers of sand and gravel. The FBS eliminates nearly all of the impurities and pathogens in the water- up to 99%! The FBS is an excellent low-tech way to purify drinking water and is used in communities around the world.

Why choose an FBS?

Providing access to drinking water is a complex and multi-faceted problem; choosing the right technology is only one aspect of the project. Other aspects like educating users, teaching good hygiene practices and monitoring are also extremely important and must be taken into consideration.

Procuring drinking water is complicated in part because the water can be contaminated in many ways and at nearly every step in the process of collecting it. Certain frequent causes of water contamination are: improper disposal of human waste (inadequate sanitary facilities), poor hygiene (failure to wash hands), livestock excrement (particularly if the water is collected in an unprotected river or stream), agricultural run-off and industrial waste. These are just a few of the ways water can become contaminated.

In numerous regions, drinking water is collected from lakes, rivers or ponds where the rate of contamination can be very high. In other places, people get their drinking water from community wells or in a borehole. Pumped water may or may not be clean. Even if it is clean, there are multiple possibilities of recontamination, in particular if the water is not kept in a secure receptacle. Because the water can be contaminated in many ways, even if the water is clean when collected, OHorizons has concentrated their efforts on the FBS, which is a point-of-use technology. As the name suggests, this technology treats the water where it is used, generally in the home. It gives maximum control to its users over the treatment of their water and reduces the risks of recontamination.

The construction manual for the filter is open-source and can be downloaded for free at the following address: https://www.biosandfilters.info/

A series of videos created to show, step-by-step, how to construct and install a concrete-lined biosand filter: https://washresources.cawst.org/fr/collections/714c93ae/how-to-build-a-biosand-filter-video-collection

The OHorizons Wooden Mold Building Manual is open source and can be downloaded for free at the following address: http://ohorizons.org/resources/Youtube

Matériaux

Construction of one wooden OHorizons mold:

- 4x8 ft. Plywood 3/4 inches thick

- Lumber 1.5x1.5 inches (8 pieces 46 cm long, 4 pieces 40 cm long, 4 pieces 35 cm long)

- 16 Bolts with hex heads and fully threaded

- 12 hinges with screws about 2.5 inches long

- 17 nuts

- 33 washers

- 75 wood screws, each 4cm long

- 60 wood screws, each 3cm long

- 1 Bolt 4-5 inches long

Construction of the concrete filter body

- Plastic tubes (polyethylene or vinyl) 6mm (1/4") ID and 9mm (3/8") OD

- Sturdy tape

- Oil (food grade)

- Brush or cloth to apply the oil

- 12 liters of cement

- 24 liters of 1mm (0.04") sand

- 12 liters of 12mm (1/2 ) gravel

- 12 liters of 6mm (1/4 ) gravel

- Water - about 7-10 liters

- Soap

Preparation of gravel and sand:

- Protection (e.g. a tarp or plastic sheets), a roof or building to prevent the sand from getting wet and being contaminated

- Clean Water

- 12mm (1/2") Gravel

- 6mm (1/4") Gravel

- 0.7 mm (0.03") Sand

n/a

Filter Installation:

- Approximately 3 liters of 12mm (1/2") washed gravel (drainage layer)

- Approximately 3 1/4 liters of 6mm (1/4") washed gravel (separating layer)

- Approximately 25 liters of washed 0.7mm (0.03 ) sand 40-80 liters (10-20 gallons) of water

- Chlorine

Outils

Construction of the concrete filter body

- Utility knife

- Source of heat if you are using polyethylene tubes (for example: propane or a kerosene torch, wood fire, electric burner)

- Wire brush, sandpaper or steel wool to clean the mold

- Level

- Wood wedges in different sizes

- 2 9/16" wrenches

- Containers to measure the sand, the gravel and the cement

- 1 1.5m (5’) metal rod (like rebar) or a piece of wood

- Rubber or wooden mallet

- Trowel

- Shovels

- 1 wrench 1-1/2"

- Hammer

- 4 wooden blocks (about 5cm square)

- Brush

Preparation of gravel and sand:

- 12mm (1/2") sieve

- 6mm (1/4") sieve

- 1mm (0.04") sieve

- 0.7mm (0.03 ) sieve

- Shovels

- Wheelbarrow (if available)

- Several large containers about 40 cm (15") deep

- Small clear container with lid

Installation d'un filtre:

- Tape measure

- A stick [about 100 cm (40") long, 2.5 cm x 5 cm (1 x 2") preferred]

- Burner/ diffuser

- Storage container

- A watch

- 1 liter graduated measuring container

- 1 m (3") of pipe that fits in with fixing to the exit pipe

- Vise (if available)

- Funnel (can be made with the top of a water bottle)

Étape 1 - How does the biosand filter work?

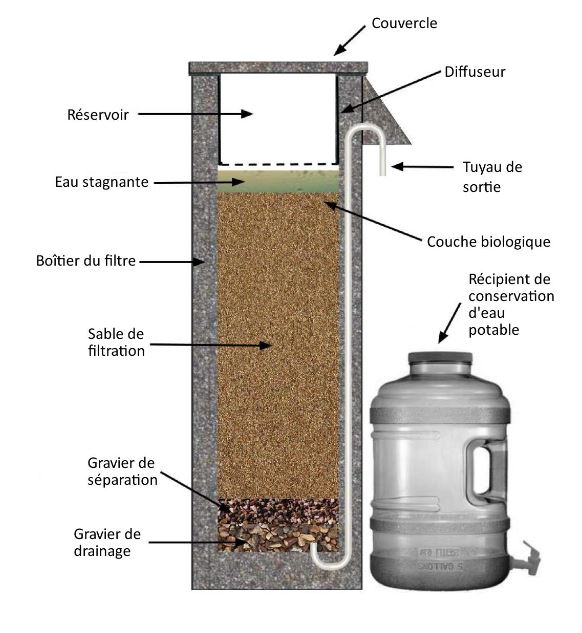

The different parts of an FBS (see photo 1) :

The bio-sand filter is composed of five distinct areas:

- The reservoir zone

- The water resting zone

- The biological zone

- The non-biological zone

- The gravel zone

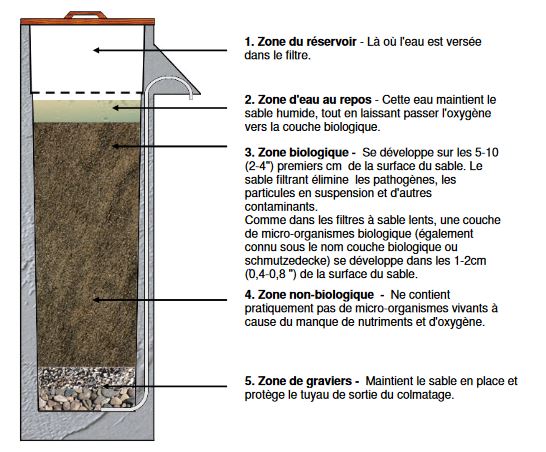

What happens to the pathogens and impurities in the filter? (see photo 2)

The pathogens and suspended materials are eliminated by a combination of physical and biological processes that take place in the biological layer and within the sand layer. These processes include: mechanical entrapment, predation, adsorption, and natural death.

- Mechanical trap : Suspended matters and pathogens are physically blocked in spaces between the grains of sand.

- Predation : Pathogens are eaten by other micro-organisms in the biological layer.

- Adsorption : Pathogens are attached one to another, to suspended matters and to the grains of sand.

- Natural death : Pathogens die or end their life cycle, because there is not enough food or oxygen for their survival.

FBS Operation :

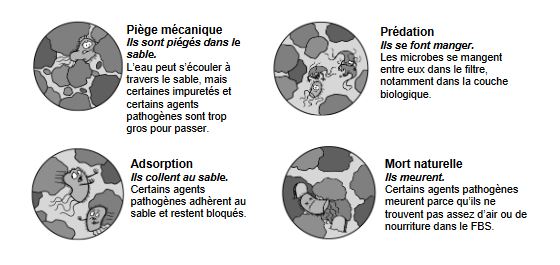

During filtration (water flows)

(see photo 3)

While water is poured into the filter, the level of water (also called the hydraulic head) is elevated and pushes the water) through the diffuser and the filter. The level of water in the reservoir drops as the water flows steadily through the sand. When the reservoir is full, the output should be 400mL per minute. The output will diminish gradually since there is less pressure to push water through the filter. The water that goes through the filter contains dissolved oxygen, nutrients and contaminants. It brings some oxygen and nutrients that are needed by the micro-organisms in the biological layer. The suspended particles and large pathogens are caught in the first layer of sand and they are clog part of the pores between the grains of sand. This clogging slows the output of the filter over time. Users may occasionally resort to a ‘’’swirl and dump’’’ maintenance procedure to restore the output flow of the filter.

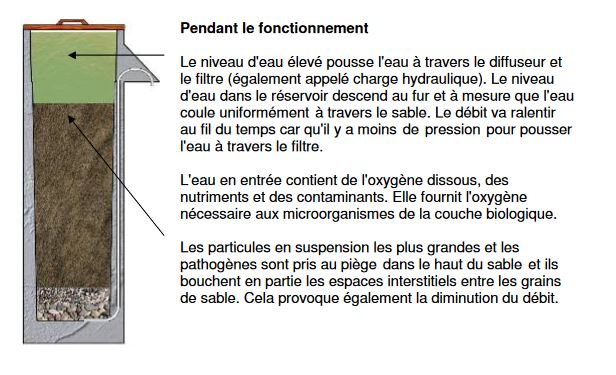

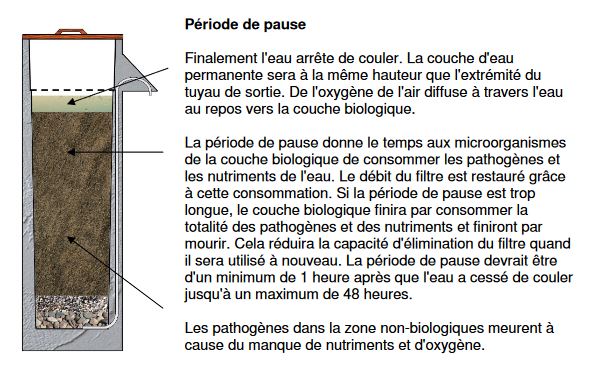

Resting period (no water flow) (see photo 4)

The water will stop flowing when the water in the reservoir gets to the same level as the end of the outlet pipe. (This is true for filters in which the outlet pipe has a diameter of 6mm. see previous page). Some of the oxygen in the air is diffused through the still water to the biological layer during the resting period. The resting period lets the microorganisms in the biological layer have time to consume the pathogens and nutrients present in the water. The pathogens in the non-biological zone (underneath the biological layer) die because they lack the nutrients and oxygen during the resting period. The resting period should last at least one hour.

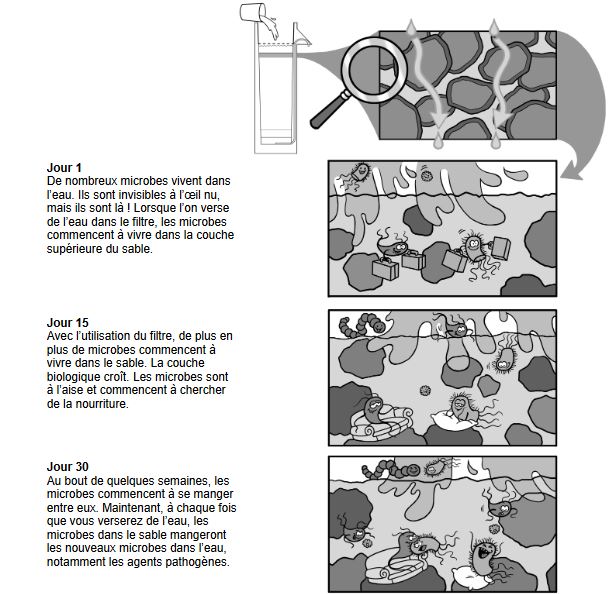

What makes the FBS special? The biological layer! (see photo 5)

In an FBS, small microbes live in the top layer of sand. We call this the BIOLOGICAL LAYER. The biological layer is very important because it makes the water drinkable. It takes about 30 days to form.

- Day 1: Many microbes live in the water. They are invisible to the naked eye, but they are there! While water travels through the filter, the microbes start living in the top layer of sand.

- Day 15: With the use of the filter, more and more microbes start to live in the sand. The biological layer grows. The microbes are at ease and start looking for food.

- Day 30: After a few weeks, the microbes start to eat each other. Now, every time that you pour water, the microbes in the sand will eat the new microbes in the water, including pathogens.

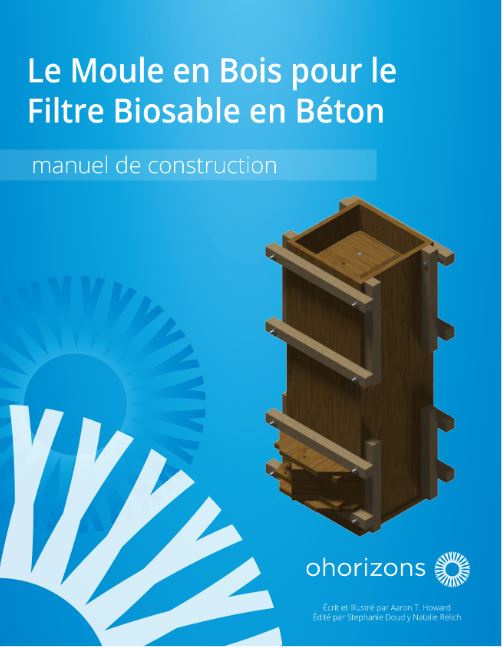

Étape 2 - OHorizons Wooden Mold Construction Manual

This manual is free and open-source. It can be downloaded at the following address: https://static1.squarespace.com/static/5afb5f6225bf020305339c10/t/5bf67b714fa51a471a435d36/1542880476379/ohorizons_LeMouleEnBois_Manuel_Francais.pdf

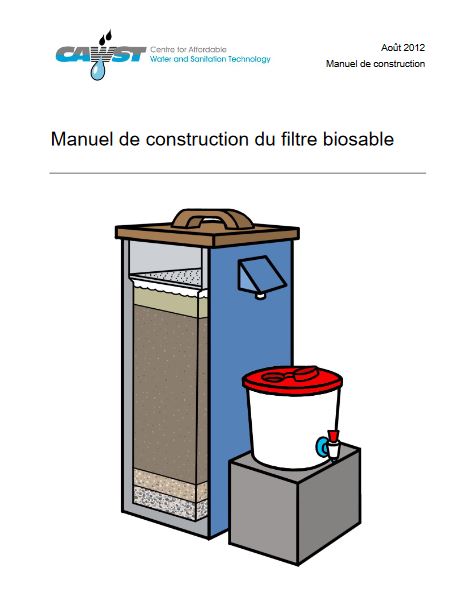

Étape 3 - Concrete Filter Construction Manual

This manual produced by the Center for Affordable Water and Sanitation Technologies (CAWST) is free and open-source. It can be downloaded at the following address: https://resources.cawst.org/construction-manual/a90b9f50/biosand-filter-construction-manual

Étape 4 - Video Series on the Construction of the Bio-Sand Filter

This video series produced by the Center for Affordable Water and Sanitation Technologies (CAWST) is designed to show, step by step how to construct and install a concrete biological sand filter. It is free and can be viewed here: https://washresources.cawst.org/fr/collections/714c93ae/how-to-build-a-biosand-filter-video-collection

Étape 5 - Frequently Asked Questions

Answers from the following document: https://static1.squarespace.com/static/5afb5f6225bf020305339c10/t/5b4c1df8758d462d957b8a49/1531715067103/french-intro-to-bsfs_ohorizons_Introduction_au_filtre_biosable.pdf

How much water can be filtered per day?

A biosand filter made from OHorizons wooden mold will filter 11 liters each use, this means that it will filter 11 liters each time it is refilled. It is recommended to fill the filter a maximum of four times per day and a minimum of once a day. This means that the owner of the filter can obtain anywhere from 11 to 44 liters of water or about 3-12 gallons each day. A maximum of four refills per day is recommended to allow for long enough rest periods between each operation of the filter.

How much does a biosand filter cost?

The cost varies depending on the place where the filter is made and the local cost of materials and labor. In general, the cost varies between 25 and 65 dollars USD per filter.

How much does a filter weigh?

An installed filter (with filter media) can weigh up to 350lb or 160kg. Once installed, the filters should never be moved. The stabilization of the sand helps to eliminate the pathogens and the sand can be disturbed in moving the filter. The concrete filter box weighs about 150lb or 70kg. If the filter must be moved, the sand and the gravel must be taken out, washed and reinstalled in the new filter location.

How much time does it take to develop the biological layer?

After approximately 30 days of use, the biological layer will be entirely developed and the filter will function at its optimal rate in eliminating pathogens. Over the course of the first 30 days, the filter removes around 70% or more of the pathogens and approximately 100% of chlorine resistant pathogens. During this period, the filtered water can be consumed, but we recommend that users also boil the water or use chlorine to ensure that the water is completely drinkable. OHorizons recommends this multi-barrier approach even beyond the initial 30 day period. Although the filter functions in an optimal way after the first month, different factors can affect its efficiency over time, like inappropriate use by the user or changes in the level of contamination of the water source. The use of a multiple-barrier approach throughout the life of the filter guarantees that users will always drink the water that is as purified as possible.

Why doesn’t the sand go down the PVC tube or pipe?

The sand is only the top layer. The bottom two lower layers of the filter are comprised of small and large gravel. The small gravel prevents the sand from flowing out and the large gravel prevents the small gravel from escaping or from obstructing the exit tube.

Other than refilling the filter with water, how is the filter maintained? How is it cleaned?

The biosand filter needs very little cleaning. Once the concrete box is completely set, it must be cleaned well with soap and water to eliminate all the residual sand or dirt. Then, it can be safely filled with sand, gravel and water in the user’s home. It is recommended to regularly wipe down the exterior, the cover and the diffuser plaque.

The filter is very simple to use, just like caring for a houseplant. The most important part of maintenance is to ensure that the biological layer stays healthy by feeding it one to four times a day with contaminated water. Once fed, the biological layer must digest and recover, so there must be at least one hour between each use. Just like a house plant, the biological layer cannot survive if there is too much or too little water. While the filter is not being used, a 5cm layer of water covers the top of the sand. This layer must be maintained or the living microorganisms may die. If cloudy or visibly dirty water is poured through the filter, the sand will accumulate dirt which will slow the flow of water. To correct this, a non invasive method that does not disturb the biological layer called stir and dump is used to clean the top of the sand and improve the flow.

Who is responsible for maintaining biosand filters?

The owner of the filter is responsible for its maintenance. The owners are usually trained in maintenance before or during the installation of a filter. OHorizons ensures that all of our partners have appropriate training in matters of maintenance and installation. These partners are available to households to answer their questions, make repairs, reeducate and provide additional assistance, as needed.

How long does a filter last? How often should the sand be replaced?

Barring exceptional circumstances that would cause a leak in the concrete housing, there should be no reason to replace the filter. If it is correctly maintained and installed, a filter can last a lifetime and the sand does not need to be replaced. If the water used is particularly cloudy or visibly dirty, the owner of the filter will regularly use the spin and dump technique to get rid of the dirt. This method removes a small quantity of sand and, over time, the filter will need more filtration sand added.

Does the filter need a pump, electricity or a mechanical system to work?

No, the biosand filter works due to the force of gravity. Gravity pulls the water down through the sand and the pipe due to a natural siphon effect. It does not need electricity or pumps. This means it is an excellent solution for areas that are not connected to an electrical grid.

Are specific types of sand needed?

Yes, the best sand is crushed rock which can be obtained from most local quarries. Crushed rock does not contain the organic matter or salt that is often found in sand from the river or the beach. The crushed rock sand is also more varied in size and shape which makes the filter more effective. The sand must be washed and sifted before being put in the filter so that only the grains of a certain size range are used and nothing harmful is introduced in the filter. The gravel must also be of varied shapes and must be washed before being placed in the filter. Please see our appendix for more information on the best type of sand to use for filtration.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português