Description

The objective is to make a manual pump to draw water from a tank for exemple.

Introduction

Matériaux

All these pieces are here in PVC for the pump : - 3 adapter 50mm-25mm - 2 couplings 50mm - 1 T 50mm-25mm

- 1 or 2 25mm elbows (depending on water outlet requirements)

- between 1 and 2 metres of 25mm tube (depending on water outlet requirements) - between 1 and 2 meters of 50mm tube - two balls over 25mm in diameter (glass balls) - 2 screws at least 50 mm long

for the piston : - between 1 and 2 meters of 40mm tube - 1 T XXmm-40mm - 1 tube cap of 40mm, if possible a little wider

paint stripper (acetone type)

Outils

- Saw - Drilling machine - Screwdriver - Pvc glue - Sandpaper - a cloth

Étape 1 - The principle

The principle of operation of this pump is very simple.

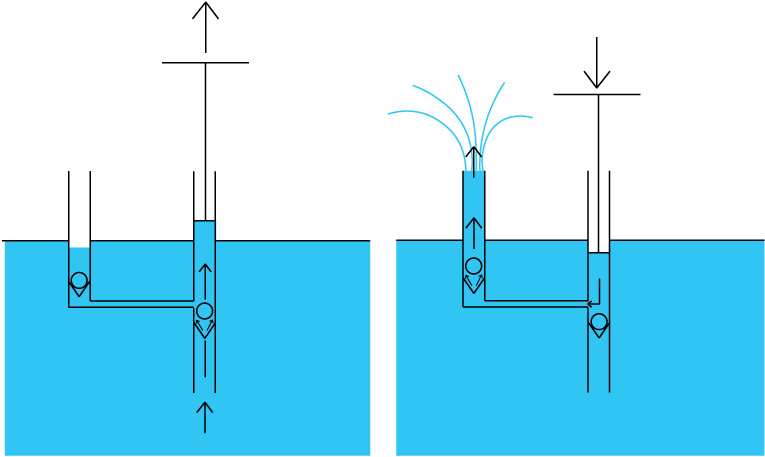

When the piston is raised, a vacuum is created. It will attract water from the pool through the anti return system from below. The other valve is in the other direction, the water from the outlet is not sucked in.

When the piston is lowered, an overpressure is created, which will close the bottom check valve, and open the other valve. The water can then come out.

This type of pump is called a "delivery pump".

Étape 2 - The preparation :

Without sticking the pieces together, the purpose of this step is to check the material.

Nest the elements as shown in the following diagram:

You can even test the operation.

To optimize : areas surrounded in blue should be as short as possible.

Étape 3 - The assembling of the handle

Once the verification is done, the assembly can begin.

You simply have to glue the elements with PVC glue and check the sealing at the end.

How to glue ? - Grind with fine sandpaper the parts to be assembled - Clean with a cloth soaked in paint stripper. - Apply the glue at the inlet of the female part and on the entire male part. - Immediately engage fully, without twisting. - Wipe off glue burrs.

The drying time is about 1h, but if the water is to be consumed, it is advisable to wait between 12h and 24h for the toxic solvents to disperse.

Étape 4 - The pump casing assembly

Glue all the pieces then once dry, drill and screw in the middle of the 50mm-50mm coupling.

You can also nail (see picture) very well by drilling with a smaller diameter.

This allows the ball to lift sufficiently to allow water to pass through, while preventing it from clogging the other end.

/!/ Make sure the ball is on the right side!

Étape 5 - The setting up

For maximum efficiency, it is ideal to seal the pipes. In SERTA, the non-movable part is poured into the concrete that forms the tank cover.

What is important is that the extension, through which the water will enter the circuit, does not touch the bottom of the reservoir, but is nevertheless close enough to be able to draw from the deepest part of the basin, and that the whole system is rigid enough to facilitate pumping.

It is advisable to position the entire system before fixing it.

Notes et références

This system is installed at SERTA (Serviço de Tecnologia Alternativa), Brazil

Improvements: link the pump to a wind turbine for continuous pumping, to a bicycle for a large quantity.

Yes

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português