Description

Produces natural gas and fertilizer from our organic waste.

Sommaire

Sommaire

- 1 Description

- 2 Sommaire

- 3 Introduction

- 4 Video d'introduction

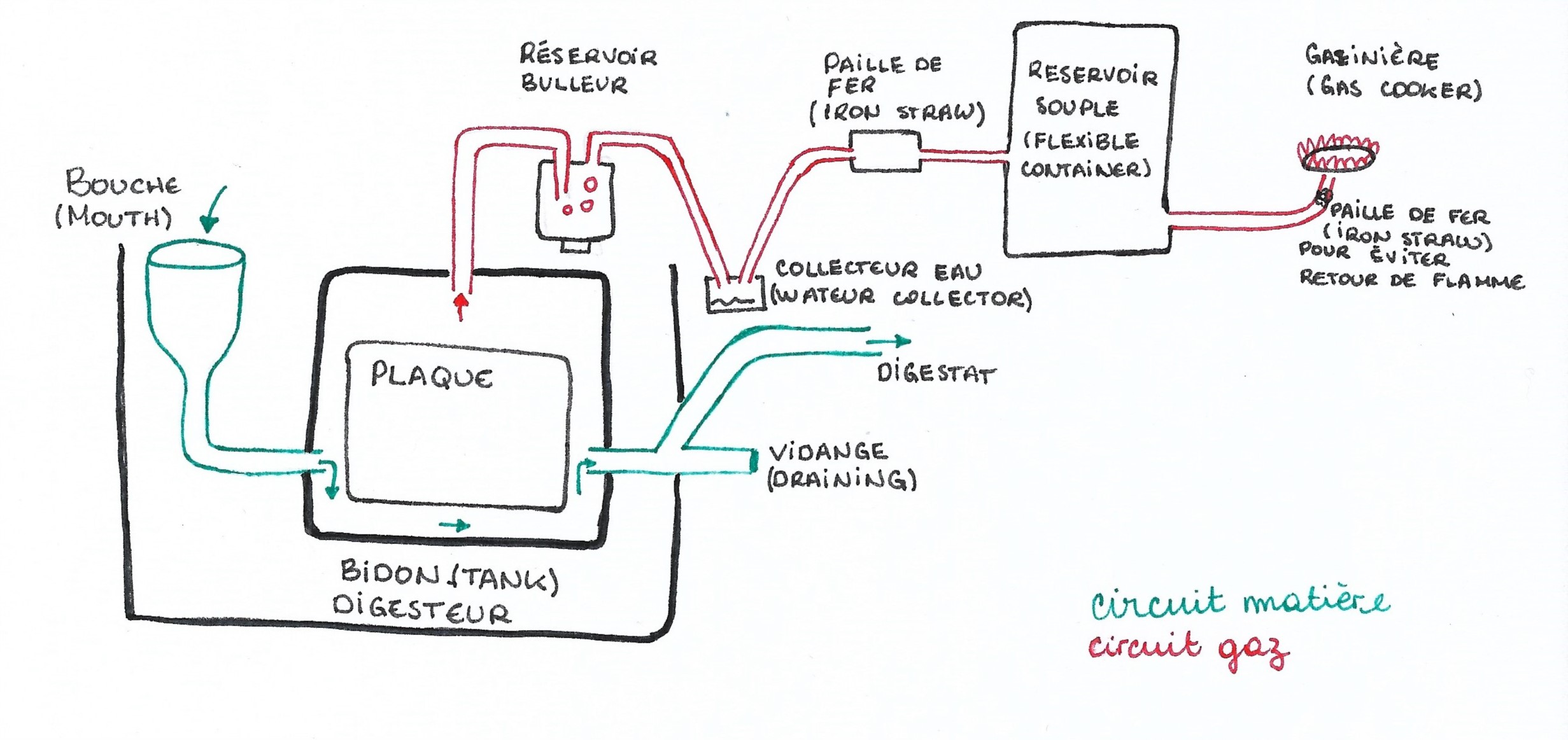

- 5 Étape 1 - Matter circuit - Digestor

- 6 Étape 2 - Matter circuit - Input

- 7 Étape 3 - Matter circuit - Overflow

- 8 Étape 4 - Matter circuit - Bonding and sealing

- 9 Étape 5 - Heat and Isolation

- 10 Étape 6 - Gas circuit

- 11 Étape 7 - Gas circuit - Digestor

- 12 Étape 8 - Methane

- 13 Étape 9 - Carbon dioxyde

- 14 Étape 10 - Water vapour

- 15 Étape 11 - Hydrogen sulphide

- 16 Étape 12 - Gas circuit - Storage

- 17 Étape 13 - Gas circuit - Flashback

- 18 Étape 14 - Gas circuit - Combustion

- 19 Étape 15 - Gas circuit - Sealing

- 20 Étape 16 - Digestor usage - Feed

- 21 Étape 17 - Inoculation

- 22 Étape 18 - Digestate

- 23 Étape 19 - Educational content to download

- 24 Notes et références

- 25 Commentaires

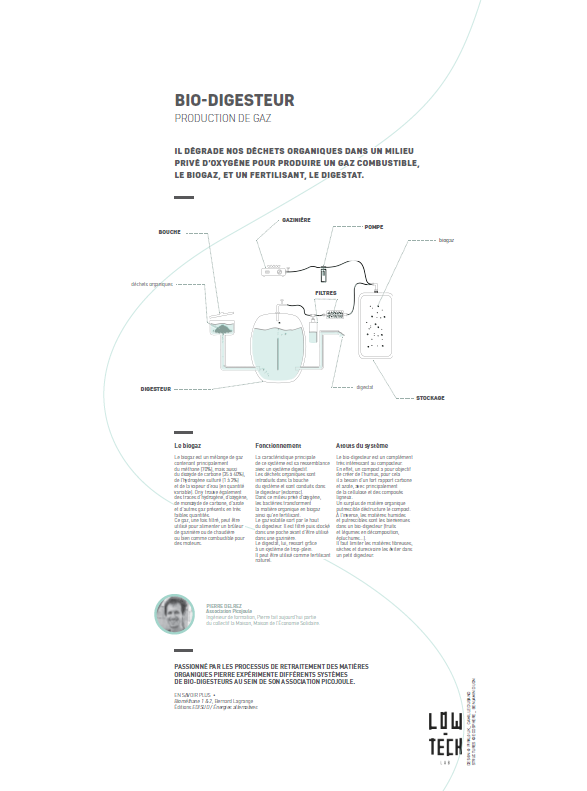

Introduction

A biodigestor is a solution to convert organic waste into fuel gas (biogas) and fertilizer (digestate). The biodigestor particularity is that digestion is done thanks to bacterias in an environment deprived from any oxygen. This situation is called anaerobic fermentation.

Biogas is a mix of different gases, containing mainly methane, which can be used for gas cookers, boilers or as fuel for engines.

Methanogen fermentation also exists in nature. For example, it happens in swamps when organic matter is decomposed underwater.

Biogas domestication happened in the beggining of the XIXth century, and the variety of biodigestors have considerably increased since then. They are particularly present in developing tropical countries, where farmers become autonomous in energy thanks to biogas production based on organic waste. Heat being an important catalyst of this reaction, small units are economically interesting in this area.

In France and other industrialized countries, the cost of energy being very low compared to workforce cost, only few small biodigestor units exist. However, many industrial units are present in wastewater treatment plants or around big breeding farms.

Different kinds of biodigestors exist. They can be continuous or discontinuous, and also have different operation temperatures (psychrophilic : 15-25°C, mesophilic : 25-45°C or thermophilic : 45 – 65°C). In this tutorial, we are studying continuous mesophilic biodigestors at 38°C, which are the most commonly used in temperate regions.

The main feature of this system is its similarity to a digestive system, as it also needs a certain temperature to be efficient, requires bacterias and receives food regularly.

In a compost, under aerobic conditions, decomposition of organic matter produces gas (H2S, H2, NH3) and an important amount of heat. Only decomposition deprived from air produces methane. It is one of the reasons why fermentation happens in a sealed tank.

In this tutorial, we will present the different components of a biodigestor (matter circuit and gas circuit) and how to use it.

This documentation realised with the association Picojoule describes fabrication of one of their micro-methanisation protypes. It does not provide full cooking gas autonomy but is a good introduction to methanisation. Hélie Marchand's half-burried digestor has a greater capacity : Biodigesteur.

These explanations are largely inspired from the work of Bertrand Lagrange in its books Biométhane 1 and 2, that we strongly recommand !

This work is free and open, do not hesitate to clarify and complete it based on your knowledge and experience.Youtube

Matériaux

Matter circuit

- 1 60 L can

- 1 160 mm plug

- 1 160-100 mm reducer

- 1 100-50 mm reducer

- 1 meter PVC 50 mm tube

- 4 45° 50 mm PVC MF bends

- 2 50 mm separable connections

- 2 50 mm through wall connectors

- 2 MM 50 mm sleeves

- 1 50 mm PVC plug

- PVC glue

- Etchant

- Joint compound for plumbing

Gas circuit

- 2 planar nuts 1/2’ for through wall gas connector

- 1 batch of planar joints

- 1 threaded tube of 1/2’

- 1 brass MF 1/2’ bend

- 1 connector FF 1/2’ gland nut

- 1 gas valve 15x21 MM

- 1 batch of hose clamps

- 1 gas pin 1/2’ F

- 5 m gas pipe

- 1 water filter

- 1 sulfur filter made of clay balls

- 2 gas valves

- 3 T gas pipes

- 1 compressed air dismountable connector

- 1 manometer

- 1 flexible 150L water tank

- 1 gas compressor

- 1 gas cooker

- 1 heat mat

Outils

- saw

- drilling machine with cylinder saw

- screwer

- cutter

- compressor

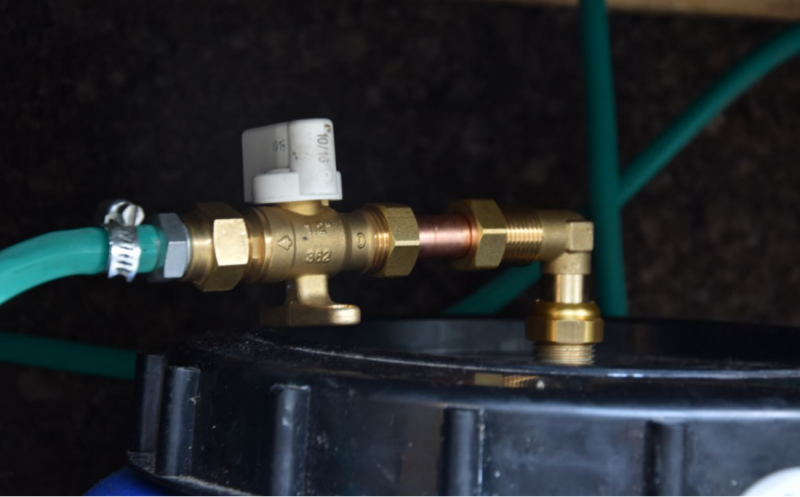

Étape 1 - Matter circuit - Digestor

Sizing

For a good digestion at 38°C, the organic matter must remain 30 days in the biodigestor. We will size the digestor volume based on this duration and on regular inputs.

Let's take an example: if the regular input is 2L per day, as the matter must stay at least 30 days, the digestor volume must be at least 60 liters.

We consider on average 1kg of waste = 1.6L = 1/2h of gas. (The calculation is made here for kitchen food waste.) The calculation must therefore be adjusted according to the daily intake and gas requirements.

Building

Degradation by the bacterias takes place in the digestor. The needed bacterias to produce methane are called methanogen bacterias. They grow in an environment deprived from oxygen, called an anaerobic environment. To remove organic matter from oxygen, it needs to be immerged into water.

- Drill two opposite holes in the digestor tank. They should be at one third of the tank height.

- Insert a through wall connector (greased beforehand) in each of the two holes,

- Grease the inside of the through wall connectors,

- Place a plate inside if the digestor, as a separation between the input and output holes. Letting matter circulate above and below the plate, it will increase the time spent by the organic matter inside of the digestor,

- Drill a hole in the tank cover and place there a through wall connector for gas,

Use teflon and planar joints on each side to seal the system,

- Grease the seal of the tank cover and close it. The grease should ensure the seal, and the cover maintains pressure,

- Install a valve after the through wall connector for gas,

Étape 2 - Matter circuit - Input

The entry of the system will be the biodigestor mouth. The installation will first be done to verify dimensions of the system, and then will be dissasembled and definitively glued.

- Put a PVC pipe in one of the digestor openings, without putting it too much inside (this would reduce matter circulation).

- Create a 90° angle using two 45° bends. On small diameter tubes, it is better to have smooth angles, as a direct 90° angle would get stuck more easily.

- Build the "mouth" with large diameter pipes. The larger the mouth is, the easier it will be to feed the digestor. A first fermentation process happens in the mouth. An unscrewable lid closes the mouth.

- Link the mouth to the digestor, placing it higher than the digestor, so that matter can circulate in the system with gravity.

Étape 3 - Matter circuit - Overflow

The overflow represents the end of the digestive system. Each time the system is fed, the same volume of digestate leaves the digestor. To make maintenance easier, a low exit in created. It allows draining of the digestor.

- Place a PVC pipe in the second hole of the digestor. It should not be too much inside, as would again limit circulation of the matter.

- Place a Y connector.

- The horizontal part will be plugged to a pipe with a cap. This will be the draining pipe.

The second part will be continued vertically, until the top of the biodigestor, using 3 45° sleeves, again to prevent blockage of the system.

- One of the PVC pipe goes outside of the system, where the digestate flows.

- The overflow should be lower than the digestor cover. This will allow to maintain a "geaseous roof" and to avoid organic matter in the gas circuit.

Étape 4 - Matter circuit - Bonding and sealing

If the blank assembly is satisfaying, we will now glue PVC components together :

- Mark each of the connectors on their junction, so that you can reassemble the system respecting alignements.

- Clean areas that will be glued.

- Bond with PVC glue.

- Let it dry.

Then we will test the sealing :

- Block temporarily the overflow outpur (for example with an air chamber and a hose clamp), screw the cap of the matter input part ("the mouth") and the draining plug.

- Put the system under pressure with a compressor flowing in the gas valve.

- Spray soapy water on the junctions. If bubles form, the sealing is not correct and the system has to be rebuild.

Étape 5 - Heat and Isolation

Heating

This kind of biodigestor is mesophile, which means that bacterias develop between 25°C ans 45°C, ideally at 38°C. Unlike compost, biodigestion create only few heat. To reach these temperatures, heat will have to be provided to the system. It is possible to heat by different means :

- compost around the digestor,

- Solar heating,

- By burning part of the produced methane.

It our case, given the small volume of the system, we are using a bedwarmer placed below the digestor.

Insulation

To prevent the digestor from loosing energy, it is important to provide a proper isolation, so that only few heat has to be provided. In addition, a good isolation limits temperature variations, to which bacterias are very sensitive. Many differents ways exist for isolation. We chose to use corkboards, but is also possible to use straw for example, which is very cheap and provides good isolation.

Étape 6 - Gas circuit

We have presented the organic matter circuit, from the mouth to the digestate production. One of the main interests of th biodigestor is that it also produces methane. In this part, we will study the different components of the gas circuit, necessary to ensure a good production and purification of the fuel.

Étape 7 - Gas circuit - Digestor

In the digestor, bacterias will produce biomethane as they degradate the organic waste. In variable proportions, it is composed of :

- Methane (CH4) 50 to 70%

- Carbon dioxyde (CO2) 35 to 40%

- Hydrogen sulphide (H2S) 1 à 3%

- Water vapor (H20) variable

There can be also traces of hydrogen, oxygen, carbon monoxyde, nitrogen, and other gases in very small quantities.

Étape 8 - Methane

Methane, CH4, belongs to the hydrocarbons family CnH2n+2, as propane (C3H8) or (C4H10). It is very light (d=0,55), and does not accumulate on the ground, unlike butane and propane, which decreases risks of explosion. Natural gas is composed mainly by methane.

To become liquid, making it easier to transport, methane has to be cooled to -165°C or compressed at a pressure of 400bars. This is only possible with industrial means, so in our case we will keep it at a gaseous state.

In terms of mass, it is the best fuel for thermic energy (12 000 Kcal/kg), but itis also the most voluminous.

Our objective is to separate methane from other gas compounds.

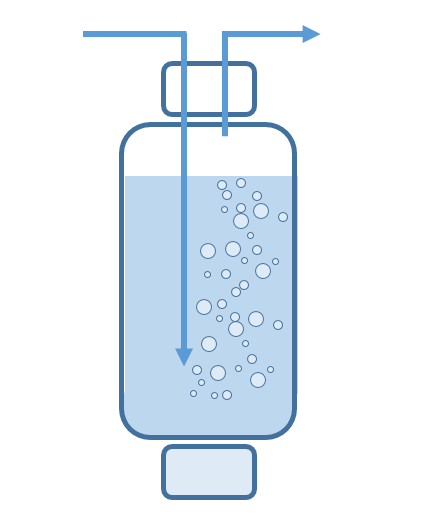

Étape 9 - Carbon dioxyde

Its proportion depends on the bacterian reactions, the temperature and the organic waste. CO2 disturbs combustion, but does not prevent it.

The easiest is to wash the gas with water. Carbon dioxyde is very soluble (878 cm3/l at 20°C), unlike methane (34 cm3/l). This water carrying CO2 can be used for agriculture irrigation, or for algeas farming such as spirulina.

- At the digestor exit, after the valve, create a gas circuit bringing the gas in a bubbler-reservoir.

- The reservoir must be filled with water.

- The gas arrival pipe dives into the water.

- The gas output pipe in on the top of the reservoir.

- A draining plug at the bottom of the bubbler-reservoir with allow collection of water carrying CO2.

Étape 10 - Water vapour

It is advisable to have a minimum of water when combustion happens, as it already produces a lot. In addition, condensation in pipes risks to block the lower parts of the gas circuit. To remove water vapour :

- Place a waste collector at the lowest point of the system.

- If the gas circuit is long, install collectors every 5 meters, at the lowest points of the circuit.

- A draining plug at the bottom the collectors allows for regular removal of water.

The bubbler reservoir can play this role of water collector if it placed at the lowest of the gas circuit.

Étape 11 - Hydrogen sulphide

Hydrogen sulphide (H2S) is burnable but produces sulfuric acid, which is highly corrosive. A good pH balance in the biodigestor avoids most of hydrogen sulphide production. To eliminate it, biomethane will go through iron oxide, or iron straw, that will be regenerated by exposing it to the air (sulfur will leave). Coal or clay balls can also serve as filters for hydrogen sulphide.

Étape 12 - Gas circuit - Storage

In the digestor, it is advised that fermentation takes place at a minimum pressure. Gas will therefore has to be evacuate along its production. Unless gas consumption is continuous and regular, it is necessary to have a storage place, supplying gas only when necessary.

Flexible reservoirs, "bladder" like, are interesting. Using a non-flexible container can be dangerous: because we will need to empty it from air befor introducing methane. Mixing air and methane can be explosive.

- Assemble the storage reservoir simultaneously to the gas circuit.

- Place a 100mbar safety valve as close as possible to the storage. It will remove gas in case of potentially dangerous overpressure.

Étape 13 - Gas circuit - Flashback

In any place where a flashback is feared, place a ball of iron straw or copper straw on the gas circuit. Through thermic conduction, it will decreases temperature and stifle the combustion. Be careful however not to compact too much the metallic straw in the pipes, otherwise it would impede a good circulation of gas.

In our case, to avoid flashbacks to the digestor and above all to the storage reservoir, we place iron straw in the closest pipe to the gas cooker.

Étape 14 - Gas circuit - Combustion

Burners setting

As it is mixed with non combustible carbon dioxyde, biomethane has a lower calorific power than propane, butane of pure methane for the same volume.

Therefore, devices functionning with these gases have a higher air admission than a gas cooker using biomethane.

To adapt standard burners to biomethane :

- Slightly close primary air arrival, with a metallic ring or with aluminium.

OR

- Disassemble the gas nozzle and use direct gas ejection.

CAUTION: flames from methane are less visible than from propane or butane, be careful not to get burned when using the gas cooker.

Other uses

Biomethane can also be used in gas lamps, heaters, or combustion engines: generators, agricultural machines, cars...

Pressure

The biodigestor and the storage are at atmospheric pressure, to ensure correct work of bacterias. The gas cooker will use 10mbar pressure. To provide this pressure:

- Install a compressor between the storage and the burner,

OR

- Press the flexible reservoir (10 cm of water). It will reduce methane production by 5% but is less expensive then buying a compressor.

Étape 15 - Gas circuit - Sealing

Each connector between a component of the circuit and a gas pipe has to be securized with a hose clamp.

Once the whole circuit is assembled, test the sealing, proceeding as for the matter circuit: put the circuit under pressure and spray soapy water on each junction. If fbubbles appear, there is a leak.

Étape 16 - Digestor usage - Feed

The biodigestor is a living system, composed by billions of bacterias, and needs to be taken care of.

Regular feeding

Ideally, the biodigestor has to be fed every day. It is possible to reduce it until once a week at the minimum. If the volume of organic matter is too important, it is advised to divide it in different "meals".

It is important to shred or grind the organic matter (knive, blender...) and to add their weight in water, in order to :

- Prevent the matter from blocking the system,

- Accelerate degradation and system productivity.

Balanced feeding

Biodigestor can be complementary to a compost. Indeed, compost creates humus, and needs a high carbon/nitrogen ratio (20 to 30), with mostly cellulose and lignous compounds. Too much putrescible organic matter will destructurate the compost.

Conversely, wet and putrescible matters are welcome in a biodigestor (fruits and vegetables, peelings ...) Fibrous, dry and hard matters need to be limited in the biodigestor. They may be the cause for blockage of the system, and remain in the digestor forming foam or a crust, that is difficult to remove.

High nitrogen input is ideal in the digestor, as it will stimulate bacterias activity. In addition, the digestate produced will be a rich fertilizer.

It is important to bring "green food" in the digestor diet. If peelings and leafstalks are not enough, it is possible to add grass.

Animal products (meat, milk, eggs...) should be avoided in the digestor, as it does not reaches high temperatures enough to detroy pathogens, unlike compost.

Oils have an important methanogen power (780 liters of methane per kilogram of oil!) but it brings acidity to the digestor, which might kill the bacterias when too important. Oils should be brought to the system sparingly.

Cooking water allows for system heating and fluidifies circulation. It also provides starch (potatoes, cereals, rice ...) that bacterias like.

Urine can be used in a regular basis. Feces are accepted sparingly, but they have a weak methanogen power, as an important part of their energetic value has already been absorbed during digestion.

pH

In acid medium, the enzymatic activity of the bacterias is inhibited. This acidity is mainly due to organic acids accumulation. In basic medium, fermentation produce hydrogen sulphide (H2S) and hydrogen (H2). Digestion can take place between pH of 6,6 and 7,6, with an optimum between 7 and 7,2.

Étape 17 - Inoculation

We have seen previously that feces have a weak methanogen power because they are already digested. However, they are important to launch bacterial activity in the digestor.

A cow, generates between 60 and 200 liters of biogas a day. We will recover part of its intestinal bacterias in its feces.

To launch the bacterial fermentation in the digestor:

- Mix fresh cow manure with its weight in water, and insert it at the entrance of the biodigestor.

If the activity of the biodigestor is stopped due to a long period without food, it would have to be inoculated again in the same way.

Digestion stabilisation until a regular production of biogas can last several weeks, during which it is advised not to disturb feeding.

Étape 18 - Digestate

The digestate from domestic biodigestor, one stabilized, is a liquid fertilizer rich in minerals and nitrogen.

You can dilute it at 10% in water, and use it every month for any kind of plants.

If animal products (meat, milk, eggs...) are part of the digestor diet, it is better not to use digestate for fruits and vegetables that will be eaten raw (strawberries, lettuce, carots...) It is better to used in orchards or non-food plants.

Étape 19 - Educational content to download

You can download an educational sheet created by the Low-tech Lab for the exhibition "In Search of a Sustainable Habitat" in the "Files" part of the tutorial (tab in the "Tools-Materials" section)

Notes et références

This section gathers the most frequently asked questions about this tutorial and the progress of the Low-tech Lab's thinking on these topics.

Advices for the filters

Cases can be made from pierced and sealed PET bottles. It is possible to place the water collector in a colder area to reach the dew point more easily, e.g. on the outside of the door.

Material supply

Steel wool can be found in a machine shop or on some sponges. Concerning the compressor, it is possible to do without it (as described in the tutorial), or to use one for refrigerators.

Self-sufficiency

The tutorial on a semi-buried digester of Hélie Marchand in Madagascar ( Biodigester) will give you more information for a larger scale biogas production. To have an idea of the dimensioning of the system to be set up, it is necessary to count on average 1kg of waste producing 1 half hour of gas.

Alternation with other gas sources

To supplement the gas production, you may want to use the stove with other gas sources. If the stove is connected to city gas, it is easy to add a three-way gas valve, to which two inputs (biogas from the biogas plant and natural gas from the network) can be connected, which can be opened as needed.

If the gas stove works with propane or butane cylinders, in this case the injector must be changed to adapt it to the gas used: methane requires a G20 type injector, while cylinder gas is used with G30/G31 injectors. This is feasible, but it will be difficult to change it every day.

References

- The first edition of this tutorial has been realised by Clément Chabot, during the Biodigestor stop of the Low-tech Tour in France.

- The documented solution was realized with Pierre and Thomas from the PicoJoule association http://www.picojoule.org/ [1] https://www.facebook.com/Picojoule/?fref=ts

- Bernard LAGRANGE, Biométhane 1. Une alternative crédible ; 2. principes-techniques, utilisations

- https://fr.wikipedia.org/wiki/Pouvoir_m%C3%A9thanog%C3%A8ne

- https://fr.wikipedia.org/wiki/Biogaz

Like all the work of the Low-tech Lab, this tutorial is collaborative, do not hesitate to add the modifications that you think are important, and to share your achievements in comments.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português