(Page créée avec « It will take about 1 hour to dry. However, if the water is intended for consumption, it is then advised to wait between 12 and 24 hours for any toxic solvents to disperse. ») |

(Mise à jour pour être en accord avec la nouvelle version de la source de la page) |

||

| (17 révisions intermédiaires par 2 utilisateurs non affichées) | |||

| Ligne 1 : | Ligne 1 : | ||

| − | {{ | + | {{Tuto Details |

| − | | | + | |Main_Picture=Pompe_manuelle__verticale__DSC00398.JPG |

| − | | | + | |Description=The objective of this tutorial is to make a manual pump which can be used for getting water out of a tank. |

| − | | | + | |Area=Water |

|Type=Tutorial | |Type=Tutorial | ||

| − | |||

| − | |||

| − | |||

|Difficulty=Easy | |Difficulty=Easy | ||

| + | |Duration=3 | ||

| + | |Duration-type=hour(s) | ||

|Cost=30 | |Cost=30 | ||

|Currency=EUR (€) | |Currency=EUR (€) | ||

| − | | | + | |Tags=pompe, eau, |

| − | |||

| − | |||

|SourceLanguage=fr | |SourceLanguage=fr | ||

|Language=en-gb | |Language=en-gb | ||

|IsTranslation=1 | |IsTranslation=1 | ||

}} | }} | ||

| − | {{ | + | {{Introduction |

|Introduction=The pump described in this tutorial is based on the design currently in use at SERTA (Serviço de Tecnologia Alternativa) in Brazil. | |Introduction=The pump described in this tutorial is based on the design currently in use at SERTA (Serviço de Tecnologia Alternativa) in Brazil. | ||

}} | }} | ||

| − | {{ | + | {{Materials |

|Material=* The parts for the pump mentioned here are all made of PVC: | |Material=* The parts for the pump mentioned here are all made of PVC: | ||

* 3 adapters 50mm-25mm | * 3 adapters 50mm-25mm | ||

| Ligne 44 : | Ligne 41 : | ||

* Cloth | * Cloth | ||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| − | |||

| − | |||

|Step_Title=Concept | |Step_Title=Concept | ||

|Step_Content=The pump works on a very simple concept. | |Step_Content=The pump works on a very simple concept. | ||

| Ligne 53 : | Ligne 48 : | ||

Pressure is created when the piston is lowered which then closes the non-return valve at the bottom and opens up the other valve. | Pressure is created when the piston is lowered which then closes the non-return valve at the bottom and opens up the other valve. | ||

| − | This allows the water is to flow out. | + | This allows the water is to flow out. |

This type of pump is called a ‘displacement pump’. | This type of pump is called a ‘displacement pump’. | ||

| + | |Step_Picture_00=Pompe_manuelle__verticale__fonctionnement.jpg | ||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| − | |||

| − | |||

|Step_Title=Preparation | |Step_Title=Preparation | ||

|Step_Content=The aim of this step is to check the equipment is in order without gluing the components together. | |Step_Content=The aim of this step is to check the equipment is in order without gluing the components together. | ||

| Ligne 68 : | Ligne 62 : | ||

For best results: the areas circled in blue must be as short as possible. | For best results: the areas circled in blue must be as short as possible. | ||

| + | |Step_Picture_00=Pompe_manuelle__verticale__DSC0013.jpg | ||

| + | |Step_Picture_01=Pompe_manuelle__verticale__DSC00132.JPG | ||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| − | |||

|Step_Title=Assembling the Handle | |Step_Title=Assembling the Handle | ||

|Step_Content=Once all checks have been completed, you can now start to assemble the components. | |Step_Content=Once all checks have been completed, you can now start to assemble the components. | ||

| Ligne 84 : | Ligne 79 : | ||

It will take about 1 hour to dry. However, if the water is intended for consumption, it is then advised to wait between 12 and 24 hours for any toxic solvents to disperse. | It will take about 1 hour to dry. However, if the water is intended for consumption, it is then advised to wait between 12 and 24 hours for any toxic solvents to disperse. | ||

| + | |Step_Picture_00=Pompe_manuelle__verticale__T.jpg | ||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| − | + | |Step_Title=Assembling the Pump Body | |

| − | |Step_Title= | + | |Step_Content=Glue all the parts together and once they have dried, drill a hole in the middle of the 50mm-50mm coupling and insert a screw. |

| − | |Step_Content= | ||

| − | + | A nail could also be used (see image) by drilling a hole of a smaller diameter. | |

| − | + | This allows the marble to be sufficiently elevated to allow the water to flow freely, preventing any obstruction at the other end. | |

| − | /!\ | + | /!\ Take care to ensure that the marble is at the right end! |

| + | |Step_Picture_00=Pompe_manuelle__verticale__DSC00135.JPG | ||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| + | |Step_Title=Implementation | ||

| + | |Step_Content=Ideally, seal the tubes for maximum efficiency. At SERTA we have set the static part in concrete which forms the cover to the tank. | ||

| + | |||

| + | The important things to take into consideration are that the extension tube, where the water goes into the system, should not actually touch the bottom but needs to be within sufficient proximity to allow the water at the very bottom to be sucked up and that the whole of the system is fairly rigid to allow a pumping action. | ||

| + | |||

| + | It is advised to place all the parts in position before gluing them together. | ||

|Step_Picture_00=Pompe_manuelle_verticale_fixation.jpg | |Step_Picture_00=Pompe_manuelle_verticale_fixation.jpg | ||

|Step_Picture_01=Pompe_manuelle__verticale__DSC00133.JPG | |Step_Picture_01=Pompe_manuelle__verticale__DSC00133.JPG | ||

| − | | | + | }} |

| − | + | {{Notes | |

| + | |Notes=<div class="mw-translate-fuzzy"> | ||

| + | System installed at SERTA (Serviço de Tecnologia Alternativa) in Brazil. | ||

| − | + | This English translation has been possible thanks to the PerMondo project: Free translation of website and documents for non-profit organisations. A project managed by Mondo Agit. Translator: Gill Barringer. (Whilst great efforts have been made to ensure the quality of this translation, the translator makes no guarantees and will accept no liability for any claims made against her in the event of any misinterpretation, errors or omissions thereof) | |

| + | </div> | ||

| − | + | [http://www/serta.org.br Serta website] | |

| + | |||

| + | Enhancements: connect the pump to a wind turbine for continuous operation or to a bicycle for large volumes. | ||

}} | }} | ||

| − | {{ | + | {{PageLang |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

| − | {{ | + | {{Tuto Status |

| − | |Complete= | + | |Complete=Published |

}} | }} | ||

| + | {{Separator}} | ||

Version actuelle datée du 14 septembre 2022 à 12:13

Description

The objective of this tutorial is to make a manual pump which can be used for getting water out of a tank.

Introduction

Matériaux

- The parts for the pump mentioned here are all made of PVC:

- 3 adapters 50mm-25mm

- 2 couplings 50mm diameter

- 1 tee 50mm-25mm

- 1 or 2 elbows 25mm (in accordance with requirements for water outlet)

- 1 - 2 metres of 25mm diameter tubing (in accordance with requirements for water outlet)

- 1 - 2 metres tubing 50mm diameter

- 2 (glass) marbles with a diameter greater than 25mm,

- 2 screws 50mm long (minimum)

For the piston:

- 1 - 2 metres of tubing 40mm,

- 1 Tee XXmm-40mm

- 1 x tube cap 40mm (or preferably slightly larger)

- acetone (or similar solvent)

Outils

- Saw

- Electric Drill

- Screwdriver

- PVC glue

- Sandpaper

- Cloth

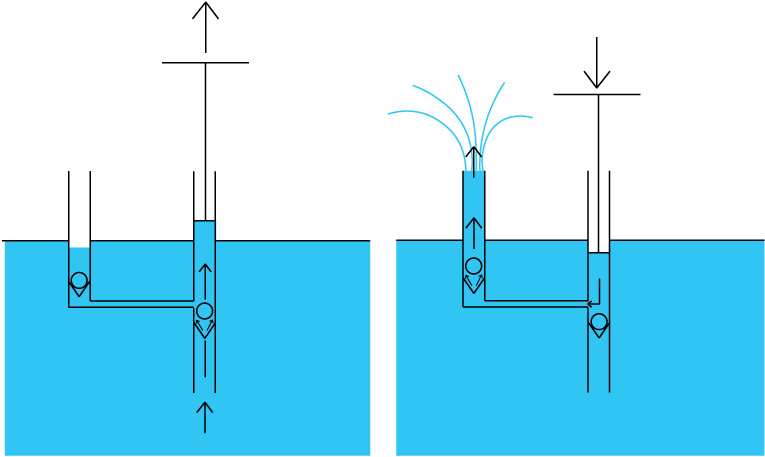

Étape 1 - Concept

The pump works on a very simple concept.

A vacuum is created when the piston is raised.The other valve is the opposite way round so the water from the outlet is not sucked in.

Pressure is created when the piston is lowered which then closes the non-return valve at the bottom and opens up the other valve. This allows the water is to flow out.

This type of pump is called a ‘displacement pump’.

Étape 2 - Preparation

The aim of this step is to check the equipment is in order without gluing the components together.

Slot the components together as per the following diagram:

You can even check if it is working or not.

For best results: the areas circled in blue must be as short as possible.

Étape 3 - Assembling the Handle

Once all checks have been completed, you can now start to assemble the components.

All that needs to be done is to glue the parts together using PVC glue and to check if the connections are watertight .

- Gluing instructions:

- Using fine sandpaper, rub down the connecting areas.

- Wipe with cloth soaked in the solvent to clean the area.

- Apply the glue inside of the opening of the female part and all over the male part.

- Immediately slot the two parts into each other without twisting.

- Wipe off any excess glue.

It will take about 1 hour to dry. However, if the water is intended for consumption, it is then advised to wait between 12 and 24 hours for any toxic solvents to disperse.

Étape 4 - Assembling the Pump Body

Glue all the parts together and once they have dried, drill a hole in the middle of the 50mm-50mm coupling and insert a screw.

A nail could also be used (see image) by drilling a hole of a smaller diameter.

This allows the marble to be sufficiently elevated to allow the water to flow freely, preventing any obstruction at the other end.

/!\ Take care to ensure that the marble is at the right end!

Étape 5 - Implementation

Ideally, seal the tubes for maximum efficiency. At SERTA we have set the static part in concrete which forms the cover to the tank.

The important things to take into consideration are that the extension tube, where the water goes into the system, should not actually touch the bottom but needs to be within sufficient proximity to allow the water at the very bottom to be sucked up and that the whole of the system is fairly rigid to allow a pumping action.

It is advised to place all the parts in position before gluing them together.

Notes et références

System installed at SERTA (Serviço de Tecnologia Alternativa) in Brazil.

This English translation has been possible thanks to the PerMondo project: Free translation of website and documents for non-profit organisations. A project managed by Mondo Agit. Translator: Gill Barringer. (Whilst great efforts have been made to ensure the quality of this translation, the translator makes no guarantees and will accept no liability for any claims made against her in the event of any misinterpretation, errors or omissions thereof)

Enhancements: connect the pump to a wind turbine for continuous operation or to a bicycle for large volumes.

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português