(Page créée avec « To reflect the maximum amount of solar beams, it is important that the beams come perpendicularly to the surface of the parabola. In summer, when the sun is high in the sk... ») |

(Mise à jour pour être en accord avec la nouvelle version de la source de la page) |

||

| (47 révisions intermédiaires par 3 utilisateurs non affichées) | |||

| Ligne 1 : | Ligne 1 : | ||

| − | {{ | + | {{Tuto Details |

|Main_Picture=Torréfacteur_solaire_de_café_20181103_101538_1_.jpg | |Main_Picture=Torréfacteur_solaire_de_café_20181103_101538_1_.jpg | ||

|Licences=Attribution (CC BY) | |Licences=Attribution (CC BY) | ||

| Ligne 15 : | Ligne 15 : | ||

|IsTranslation=1 | |IsTranslation=1 | ||

}} | }} | ||

| − | {{ | + | {{Introduction |

|Introduction=Several steps need to be considered in order to turn the coffee grain growing on its tree into the steaming hot drink waking you up every morning. | |Introduction=Several steps need to be considered in order to turn the coffee grain growing on its tree into the steaming hot drink waking you up every morning. | ||

| Ligne 21 : | Ligne 21 : | ||

Coffee is one of the main exported product of Peru. At the Granja Ecologica in Huyro, Peru, students and professors from the PUCP University have developed different low tech tools. In this region where coffee is being grown, they created a coffee solar roaster using a cement mixer. | Coffee is one of the main exported product of Peru. At the Granja Ecologica in Huyro, Peru, students and professors from the PUCP University have developed different low tech tools. In this region where coffee is being grown, they created a coffee solar roaster using a cement mixer. | ||

| + | Designed for the use of a family or a community more than for an industrial use, this roaster can roast 4kg of coffee within 20 minutes. It allows the communities living in coffee plantations to consume their own production, while controling the process of making coffee. Thus, these communities do not have to buy coffee sold on the market, which is usually roasted and packaged on the other side of the world. | ||

| + | |||

| + | Roasting coffee using a pan takes a long time, as it is always necessary to stir in the grains. The cement mixer allows a homogeneous grain roasting and we can let the process run while doing something else. | ||

| + | |||

| + | The solar coffee roaster saves energy, time and increase the independancy of the communities living in coffee plantations. | ||

Here is how to built such a machine. Our goal is to inspired and encourage the construction of machines using salvage materials. You can adapt this device to your needs, the material and tools you have at your disposal! | Here is how to built such a machine. Our goal is to inspired and encourage the construction of machines using salvage materials. You can adapt this device to your needs, the material and tools you have at your disposal! | ||

| + | <div class="mw-translate-fuzzy"> | ||

We are two French students exploring low technologies in South America. Do not hesitate to follow our adventure here : https://www.facebook.com/LAtelierLowTech/ | We are two French students exploring low technologies in South America. Do not hesitate to follow our adventure here : https://www.facebook.com/LAtelierLowTech/ | ||

| + | </div> | ||

| + | }} | ||

| + | {{TutoVideo | ||

| + | |VideoType=Youtube | ||

| + | |VideoURLYoutube=https://youtu.be/aDjp2kFA5og | ||

}} | }} | ||

| − | {{ | + | {{Materials |

| − | |Material= | + | |Step_Picture_00=Torréfacteur_solaire_de_café_IMG_20181211_231955.jpg |

| − | * | + | |Step_Picture_01=Torréfacteur_solaire_de_café_20181212_183129.jpg |

| − | * | + | |Material=Roaster: |

| − | * | + | *Cement mixer, |

| − | * | + | *Black painting, |

| − | + | *Aluminum sheets, | |

| − | * | + | *Isolating material (fiberglass, rock wool, foam,..) |

| − | * | + | Parabola: |

| − | + | *Stainless steel or aluminum bars, | |

| − | * | + | *Metal frame, sheets of metal, |

| − | + | *Wires | |

| − | * | + | Mechanical par: |

| − | * | + | *Belt or chain, |

| − | * | + | *Gears (toothed wheels), |

| − | |Tools=* | + | *Handle or motor or water wheel |

| − | * | + | |Tools=*Paint brush, |

| − | * | + | *Wire cutter, |

| − | * | + | *Flat-nose pliers, |

| − | * ( | + | *Spanner, |

| − | * ( | + | *(welding material), |

| + | *(drill- screw-gun) | ||

| + | * Protection equipment: glasses, gloves, ear defenders | ||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| − | + | |Step_Title=The solar coffee roaster | |

| + | |Step_Content=The roaster is made of 3 different parts : | ||

| + | *The roaster itself, using a salvage cement mixer | ||

| + | *The solar parabola, which concentrates solar energy into the roaster | ||

| + | *A mechanical part, which makes the roaster turn | ||

|Step_Picture_00=Torréfacteur_solaire_de_café_20181103_101538_1_.jpg | |Step_Picture_00=Torréfacteur_solaire_de_café_20181103_101538_1_.jpg | ||

|Step_Picture_01=Torréfacteur_solaire_de_café_Diapositiva2.JPG | |Step_Picture_01=Torréfacteur_solaire_de_café_Diapositiva2.JPG | ||

| Ligne 55 : | Ligne 72 : | ||

|Step_Picture_03=Torréfacteur_solaire_de_café_20181103_101419_1_.jpg | |Step_Picture_03=Torréfacteur_solaire_de_café_20181103_101419_1_.jpg | ||

|Step_Picture_04=Torréfacteur_solaire_de_café_20181103_101147_1_.jpg | |Step_Picture_04=Torréfacteur_solaire_de_café_20181103_101147_1_.jpg | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| − | |||

| − | |||

| − | |||

|Step_Title=The roaster | |Step_Title=The roaster | ||

|Step_Content=The roaster is built using a small cement mixer, whose inside walls are painted in black in order to convert the solar energy into thermal energy. | |Step_Content=The roaster is built using a small cement mixer, whose inside walls are painted in black in order to convert the solar energy into thermal energy. | ||

The cement mixers outside walls are isolated using an aluminum coating and a thick coat of isolating material (depending on the materials you have at your command: fiberglass, rock wool, isolating foam). The goal is to keep the heat inside the cement mixer so that it does not escape through the walls. | The cement mixers outside walls are isolated using an aluminum coating and a thick coat of isolating material (depending on the materials you have at your command: fiberglass, rock wool, isolating foam). The goal is to keep the heat inside the cement mixer so that it does not escape through the walls. | ||

| + | |Step_Picture_00=Torréfacteur_solaire_de_café_20181103_100954_1_.jpg | ||

| + | |Step_Picture_01=Torréfacteur_solaire_de_café_20181103_101017_1_.jpg | ||

| + | |Step_Picture_02=Torréfacteur_solaire_de_café_20181103_101008_1_.jpg | ||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|Step_Title=The Scheffler parabola | |Step_Title=The Scheffler parabola | ||

| − | |Step_Content=The Scheffler parabola is a piece of sphere covered by sheets of metal, which concentrate the solar beams at its center. The cement mixer should be placed in the middle of this sphere. | + | |Step_Content=The Scheffler parabola is a piece of sphere covered by sheets of metal, which concentrate the solar beams at its center. The cement mixer should be placed in the middle of this sphere. |

The size of the parabola depends on the quality of the materials available and the quantity of heat you need, knowing that a bigger parabola will provide more heat. | The size of the parabola depends on the quality of the materials available and the quantity of heat you need, knowing that a bigger parabola will provide more heat. | ||

| Ligne 84 : | Ligne 90 : | ||

The roasting process is generally undertaking around 200°C. | The roasting process is generally undertaking around 200°C. | ||

| − | The stainless steel or aluminium frame is built on a foot which allows it to rotate in order to | + | The stainless steel or aluminium frame is built on a foot which allows it to rotate in order to orientate the sun steams toward the cement mixer. |

To reflect the maximum amount of solar beams, it is important that the beams come perpendicularly to the surface of the parabola. In summer, when the sun is high in the sky, the parabola should be placed horizontally whereas during the winter, when the sun is low, it should be placed vertically. | To reflect the maximum amount of solar beams, it is important that the beams come perpendicularly to the surface of the parabola. In summer, when the sun is high in the sky, the parabola should be placed horizontally whereas during the winter, when the sun is low, it should be placed vertically. | ||

| − | + | According to the materials you have, they could be assembled using a welder, screws or wires. | |

| − | + | A grid-patterned structure is then added to the frame using a metal support. | |

| − | + | Pierce the sheets of metal at their extremities | |

| − | + | Fix the sheets of metal on the metal frame using wires | |

| + | |Step_Picture_00=Torréfacteur_solaire_de_café_20181103_101419_1_.jpg | ||

| + | |Step_Picture_01=Torréfacteur_solaire_de_café_Diapositiva3.JPG | ||

| + | |Step_Picture_02=Torréfacteur_solaire_de_café_20181103_101242_1_.jpg | ||

| + | |Step_Picture_03=Torréfacteur_solaire_de_café_20181103_101353_1_.jpg | ||

| + | |Step_Picture_04=Torréfacteur_solaire_de_café_Diapositiva4.JPG | ||

| + | |Step_Picture_05=Torréfacteur_solaire_de_café_Diapositiva5.JPG | ||

}} | }} | ||

| − | {{ | + | {{Tuto Step |

| + | |Step_Title=The mechanical transmitting part | ||

| + | |Step_Content=The mechanical gears which are already part of the cement mixer can be used. However , if the feet disturb the transmission, it could be better to modify the feet, as we had to do. | ||

| + | |||

| + | The blades inside the cement mixer are turning in order to continuously mix the coffee grains and obtain a homogeneous roasting, without burning the grains. The roasting process takes about 20 minutes. | ||

| + | |||

| + | The rotating movement could be done in several ways: | ||

| + | |||

| + | *Using the hands : a handle could be directly fixed to the cement mixer's gears. Undertaking the roasting process manually for 20 min could however be tiring. | ||

| + | |||

| + | *Using a generator: the toothed wheels of the cement mixer's gears could be linked to the rotation axis of a motor, using a belt or a chain. This motor could be fed thanks to a generator, the electrical network or batteries which would store the energy from solar panels, wind or water turbines. In this way, the motor will make the roaster rotate. | ||

| + | |||

| + | *Using a water turbine: if there is a stream in the area, the toothed wheels of the cement mixer and the rotation axis of a water wheel could be linked together using a belt of a chain. The water wheel will then transmit its rotation movement to the roaster. | ||

|Step_Picture_00=Torréfacteur_solaire_de_café_20181103_101027_1_.jpg | |Step_Picture_00=Torréfacteur_solaire_de_café_20181103_101027_1_.jpg | ||

|Step_Picture_01=Torréfacteur_solaire_de_café_20181103_101130_1_.jpg | |Step_Picture_01=Torréfacteur_solaire_de_café_20181103_101130_1_.jpg | ||

| Ligne 103 : | Ligne 127 : | ||

|Step_Picture_04=Torréfacteur_solaire_de_café_Diapositiva7.JPG | |Step_Picture_04=Torréfacteur_solaire_de_café_Diapositiva7.JPG | ||

|Step_Picture_05=Torréfacteur_solaire_de_café_Diapositiva8.JPG | |Step_Picture_05=Torréfacteur_solaire_de_café_Diapositiva8.JPG | ||

| − | | | + | }} |

| − | + | {{Notes | |

| + | |Notes=You will see different step occurring during the roasting process: | ||

| + | |||

| + | The fermented coffee grains would first dehydrate. | ||

| + | |||

| + | Then they will turn into light brown and will finally make some noise (crack). | ||

| + | |||

| + | A cooling step is then required before grinding the grain | ||

| − | + | Thank you to Hassan Hadzich and Diana Figueroa for their help and warm welcoming at la Granja Ecologica. | |

| − | + | PUCP is the Pontificia Universidad Católica del Perú, a private university in Lima, Peru. | |

| − | + | ||

| − | + | https://www.pucp.edu.pe/ | |

| − | + | ||

| − | + | The Grupo de Apoyo al Sector Rural is a group made of students and professors from the PUCP, created 25 years ago and undertaking different low tech and renewable energy projects. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | http://gruporural.pucp.edu.pe/listado-proyectos/ | |

| − | + | The first coffee solar roaster was made in the Café Compadre in Lima, Peru: https://www.facebook.com/cafecompadre/ | |

| − | + | To build the Scheffler parabola you can check this website: http://www.solare-bruecke.org/index.php/es/die-scheffler-reflektoren/bauanleitungen | |

| + | }} | ||

| + | {{PageLang | ||

}} | }} | ||

| − | {{ | + | {{Tuto Status |

|Complete=Published | |Complete=Published | ||

}} | }} | ||

| + | {{Separator}} | ||

Version actuelle datée du 8 décembre 2020 à 08:52

Description

Solar coffee roaster made using a cement mixer

Introduction

Several steps need to be considered in order to turn the coffee grain growing on its tree into the steaming hot drink waking you up every morning.

After being picked from the tree, the fruit must soak into the water and its husk must be peeled. The grain should then ferment and being roasted before being grinded. This roasting is giving the grain all its flavour.

Coffee is one of the main exported product of Peru. At the Granja Ecologica in Huyro, Peru, students and professors from the PUCP University have developed different low tech tools. In this region where coffee is being grown, they created a coffee solar roaster using a cement mixer. Designed for the use of a family or a community more than for an industrial use, this roaster can roast 4kg of coffee within 20 minutes. It allows the communities living in coffee plantations to consume their own production, while controling the process of making coffee. Thus, these communities do not have to buy coffee sold on the market, which is usually roasted and packaged on the other side of the world.

Roasting coffee using a pan takes a long time, as it is always necessary to stir in the grains. The cement mixer allows a homogeneous grain roasting and we can let the process run while doing something else.

The solar coffee roaster saves energy, time and increase the independancy of the communities living in coffee plantations.

Here is how to built such a machine. Our goal is to inspired and encourage the construction of machines using salvage materials. You can adapt this device to your needs, the material and tools you have at your disposal!

We are two French students exploring low technologies in South America. Do not hesitate to follow our adventure here : https://www.facebook.com/LAtelierLowTech/

Youtube

Matériaux

Roaster:

- Cement mixer,

- Black painting,

- Aluminum sheets,

- Isolating material (fiberglass, rock wool, foam,..)

Parabola:

- Stainless steel or aluminum bars,

- Metal frame, sheets of metal,

- Wires

Mechanical par:

- Belt or chain,

- Gears (toothed wheels),

- Handle or motor or water wheel

Outils

- Paint brush,

- Wire cutter,

- Flat-nose pliers,

- Spanner,

- (welding material),

- (drill- screw-gun)

- Protection equipment: glasses, gloves, ear defenders

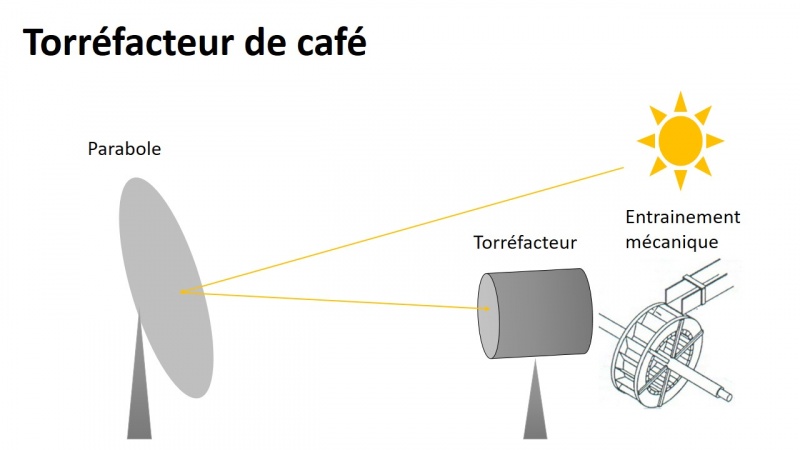

Étape 1 - The solar coffee roaster

The roaster is made of 3 different parts :

- The roaster itself, using a salvage cement mixer

- The solar parabola, which concentrates solar energy into the roaster

- A mechanical part, which makes the roaster turn

Étape 2 - The roaster

The roaster is built using a small cement mixer, whose inside walls are painted in black in order to convert the solar energy into thermal energy.

The cement mixers outside walls are isolated using an aluminum coating and a thick coat of isolating material (depending on the materials you have at your command: fiberglass, rock wool, isolating foam). The goal is to keep the heat inside the cement mixer so that it does not escape through the walls.

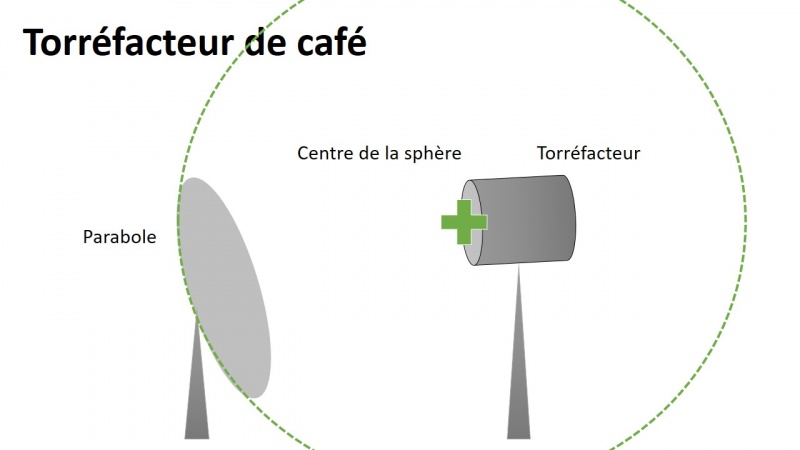

Étape 3 - The Scheffler parabola

The Scheffler parabola is a piece of sphere covered by sheets of metal, which concentrate the solar beams at its center. The cement mixer should be placed in the middle of this sphere.

The size of the parabola depends on the quality of the materials available and the quantity of heat you need, knowing that a bigger parabola will provide more heat.

The roasting process is generally undertaking around 200°C.

The stainless steel or aluminium frame is built on a foot which allows it to rotate in order to orientate the sun steams toward the cement mixer.

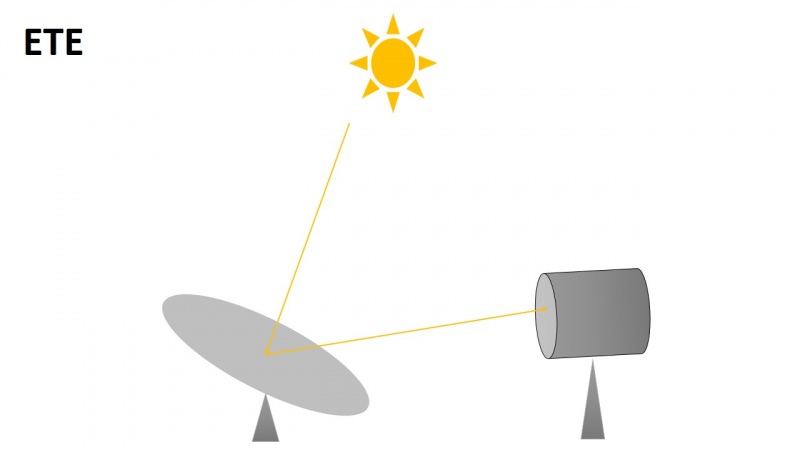

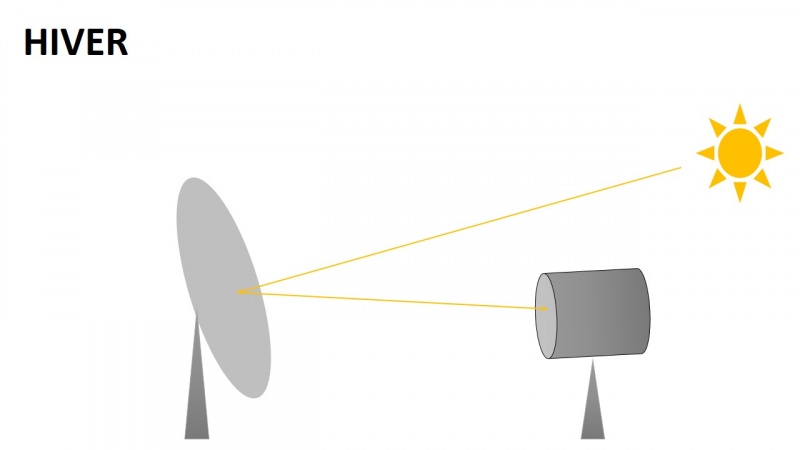

To reflect the maximum amount of solar beams, it is important that the beams come perpendicularly to the surface of the parabola. In summer, when the sun is high in the sky, the parabola should be placed horizontally whereas during the winter, when the sun is low, it should be placed vertically.

According to the materials you have, they could be assembled using a welder, screws or wires.

A grid-patterned structure is then added to the frame using a metal support.

Pierce the sheets of metal at their extremities

Fix the sheets of metal on the metal frame using wires

Étape 4 - The mechanical transmitting part

The mechanical gears which are already part of the cement mixer can be used. However , if the feet disturb the transmission, it could be better to modify the feet, as we had to do.

The blades inside the cement mixer are turning in order to continuously mix the coffee grains and obtain a homogeneous roasting, without burning the grains. The roasting process takes about 20 minutes.

The rotating movement could be done in several ways:

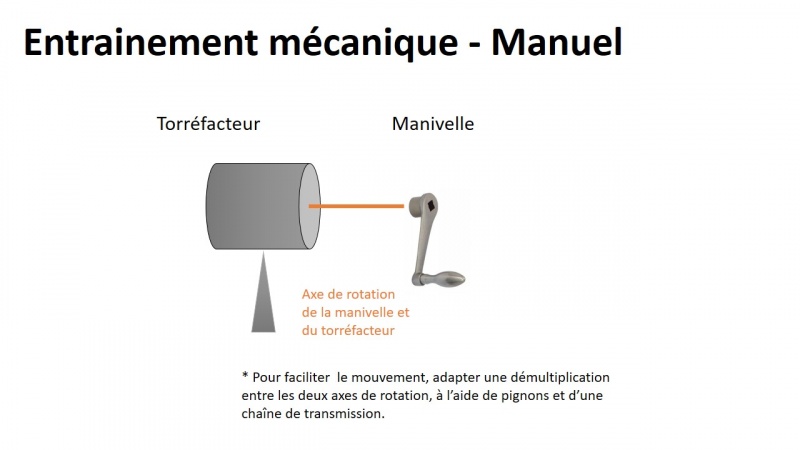

- Using the hands : a handle could be directly fixed to the cement mixer's gears. Undertaking the roasting process manually for 20 min could however be tiring.

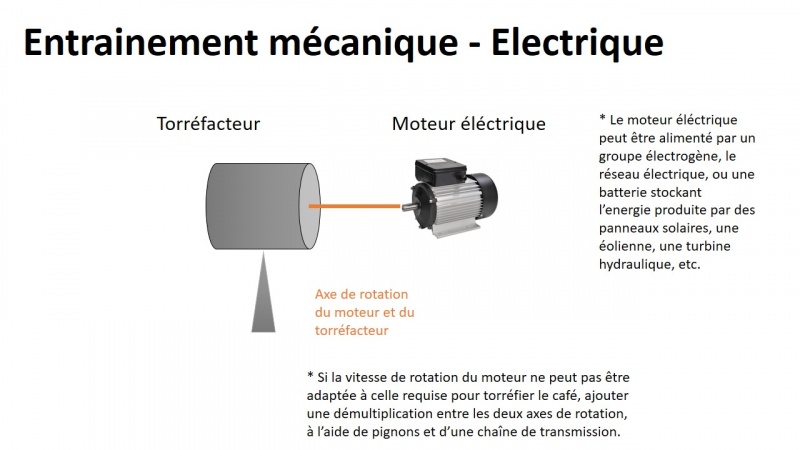

- Using a generator: the toothed wheels of the cement mixer's gears could be linked to the rotation axis of a motor, using a belt or a chain. This motor could be fed thanks to a generator, the electrical network or batteries which would store the energy from solar panels, wind or water turbines. In this way, the motor will make the roaster rotate.

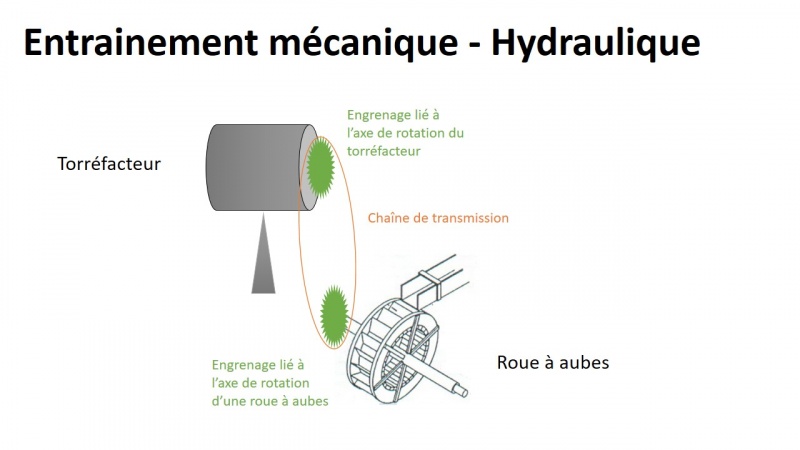

- Using a water turbine: if there is a stream in the area, the toothed wheels of the cement mixer and the rotation axis of a water wheel could be linked together using a belt of a chain. The water wheel will then transmit its rotation movement to the roaster.

Notes et références

You will see different step occurring during the roasting process:

The fermented coffee grains would first dehydrate.

Then they will turn into light brown and will finally make some noise (crack).

A cooling step is then required before grinding the grain

Thank you to Hassan Hadzich and Diana Figueroa for their help and warm welcoming at la Granja Ecologica.

PUCP is the Pontificia Universidad Católica del Perú, a private university in Lima, Peru.

The Grupo de Apoyo al Sector Rural is a group made of students and professors from the PUCP, created 25 years ago and undertaking different low tech and renewable energy projects.

http://gruporural.pucp.edu.pe/listado-proyectos/

The first coffee solar roaster was made in the Café Compadre in Lima, Peru: https://www.facebook.com/cafecompadre/

To build the Scheffler parabola you can check this website: http://www.solare-bruecke.org/index.php/es/die-scheffler-reflektoren/bauanleitungen

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português