(Page créée avec « Pack the first tank with plastic ») |

(Page créée avec « https://en.wikipedia.org/wiki/Pyrolysis ») |

||

| (8 révisions intermédiaires par le même utilisateur non affichées) | |||

| Ligne 37 : | Ligne 37 : | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

|Step_Title=Pack the first tank with plastic | |Step_Title=Pack the first tank with plastic | ||

| − | |Step_Content= | + | |Step_Content=For this test, plastic waste is mostly polypropylene. |

|Step_Picture_00=Pyrolyseur_de_plastique_IMG_0925.JPG | |Step_Picture_00=Pyrolyseur_de_plastique_IMG_0925.JPG | ||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title= | + | |Step_Title=Preheat the second tank |

| − | |Step_Content= | + | |Step_Content=Preheating is necessary. It allows for the condensation of gases at high temperature before passing through the last two tanks. |

|Step_Picture_00=Pyrolyseur_de_plastique_IMG_0928.JPG | |Step_Picture_00=Pyrolyseur_de_plastique_IMG_0928.JPG | ||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title= | + | |Step_Title=Formation of residual gas |

| − | |Step_Content= | + | |Step_Content=Let plastic waste consume itself until non-condensable gas forms. It comes as an addition to the gas initially used. For this test, 125mL of canister gas has been used, to which has been added residual gas. |

|Step_Picture_00=Pyrolyseur_de_plastique_IMG_0931.JPG | |Step_Picture_00=Pyrolyseur_de_plastique_IMG_0931.JPG | ||

}} | }} | ||

{{ {{tntn|Tuto Step}} | {{ {{tntn|Tuto Step}} | ||

| − | |Step_Title= | + | |Step_Title=Retrieval of fuel |

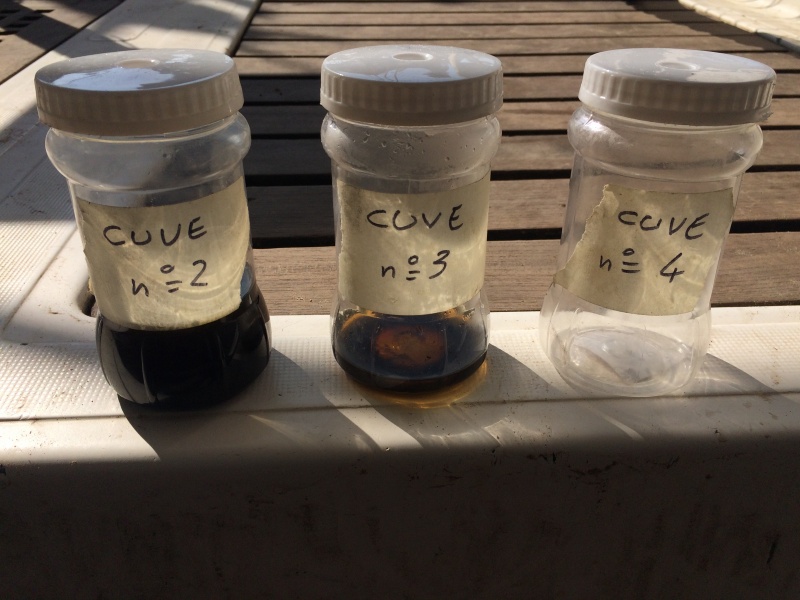

| − | |Step_Content= | + | |Step_Content=Here, the machine was heated during roughly one hour. Switch off the system and let it cool down before opening the tanks. We get around 125mL of fuel in tank n°2 and 30mL of fuel in tank n°3. |

| − | * | + | *Result of test to confirm in the lab |

|Step_Picture_00=Pyrolyseur_de_plastique_IMG_0954.JPG | |Step_Picture_00=Pyrolyseur_de_plastique_IMG_0954.JPG | ||

}} | }} | ||

{{ {{tntn|Notes}} | {{ {{tntn|Notes}} | ||

| − | |Notes=https:// | + | |Notes=https://en.wikipedia.org/wiki/Pyrolysis |

}} | }} | ||

{{ {{tntn|Tuto Status}} | {{ {{tntn|Tuto Status}} | ||

Version du 11 septembre 2019 à 18:27

Description

Produce fuel from plastic

Introduction

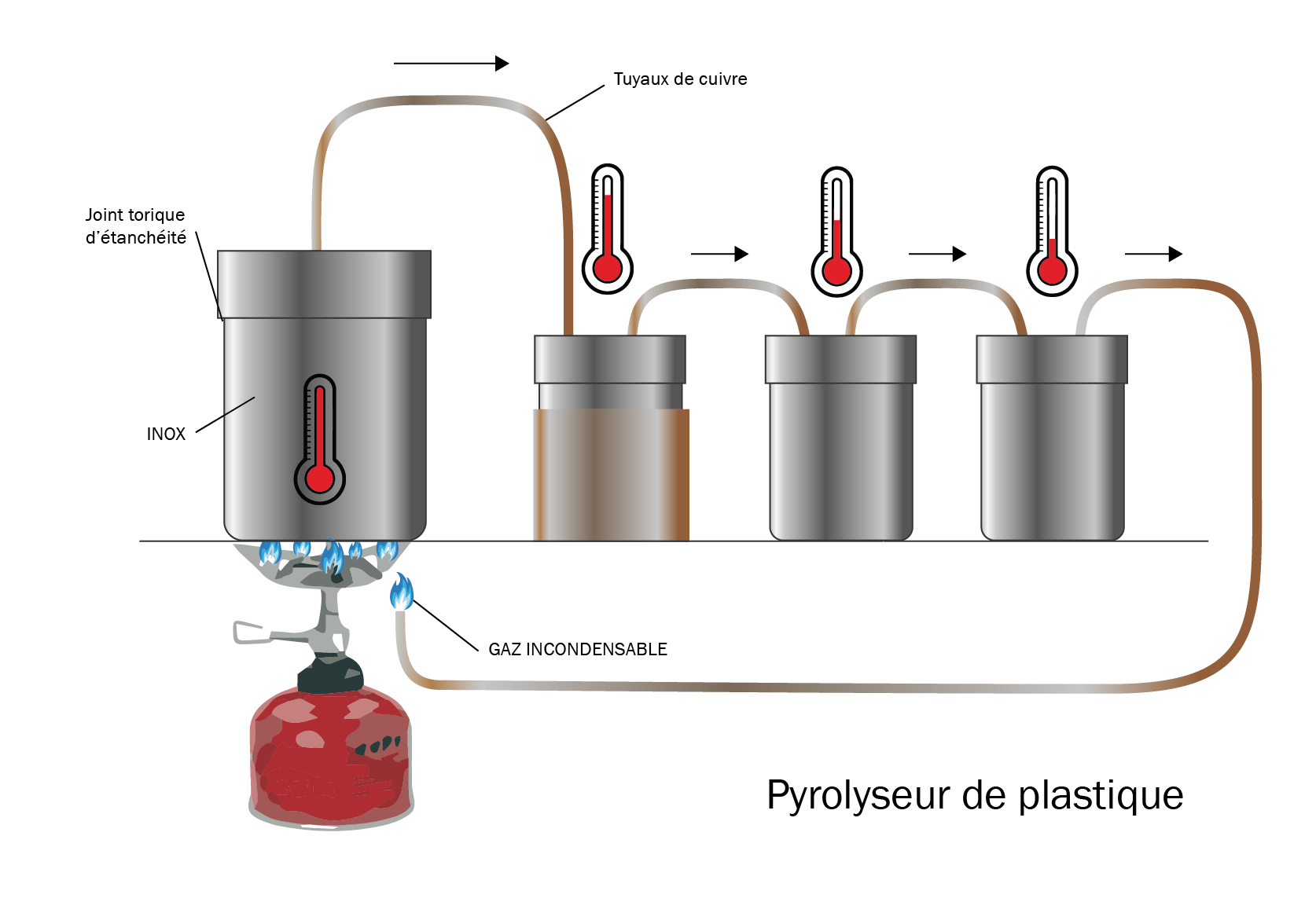

Plastic pyrolysis is a distillation process that allows plastic waste to be converted into fuel. Plastic waste is heated above 400°C in a first tank into a gas. Depending on condensation (cooling) temperatures, several types of fuel are produced : - between 390 and 170°C, the gas condensates into diesel fuel. - between 210 and 20°C, the gas condensates into gasoline. - below 20°C, there remains non-condensable residual gas that can be burned to provide heat to the process.

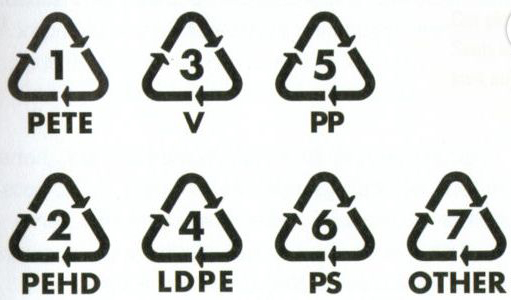

In this prototype, we are only using polypropylene (PP) and/or high density polyethylene (HDPE) and low density (LDPE). Please note that using mostly polypropylene will produce more gasoline, while using mostly polyethylene will produce more diesel fuel. It is however possible to mix both.

Matériaux

- 1 large stainless steel tank with lid

- 3 small stainless steel tanks

- copper pipes (diameter 6mm)

- 7 copper uniseal joint (for watertightness of joints)

- O-ring (for watertightness of tanks)

- Plastic waste PP and/or HDPE/LDPE

Outils

- Solder

- A heating system (min. 400°C)

- butane/propane gas canister (375mL)

Étape 2 - Preheat the second tank

Preheating is necessary. It allows for the condensation of gases at high temperature before passing through the last two tanks.

Étape 3 - Formation of residual gas

Let plastic waste consume itself until non-condensable gas forms. It comes as an addition to the gas initially used. For this test, 125mL of canister gas has been used, to which has been added residual gas.

Étape 4 - Retrieval of fuel

Here, the machine was heated during roughly one hour. Switch off the system and let it cool down before opening the tanks. We get around 125mL of fuel in tank n°2 and 30mL of fuel in tank n°3.

- Result of test to confirm in the lab

Notes et références

https://en.wikipedia.org/wiki/Pyrolysis

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português