Description

A ceramic water filter is a system for purifying unsanitary water. This tutorial aims to show how a ceramic water filter works and how to build one on a semi-industrial scale.

Sommaire

Sommaire

- 1 Description

- 2 Sommaire

- 3 Introduction

- 4 Video d'introduction

- 5 Étape 1 - Step 1 – how it works - role of the different materials

- 6 Étape 2 - Step 2 – how it works - Efficacy

- 7 Étape 3 - Step 3 - Production - Summary of steps

- 8 Étape 4 - Step 4 – Production - Preparation of raw materials

- 9 Étape 5 - Step 5 – Production - Mixing of raw materials

- 10 Étape 6 - Step 6 - Production - Forming clay cubes for the press

- 11 Étape 7 - Step 7 - Production - Pressing the clay cubes to give them the shape of the filter

- 12 Étape 8 - Step 8 - Production - Finishing of the surface and marking/numbering each filter

- 13 Étape 9 - Step 9 - Production - Drying the filters

- 14 Étape 10 - Step 10 – Production – firing filters in an oven

- 15 Étape 11 - Step 11 - Production - Flow testing of each filter

- 16 Étape 12 - Step 12 - Production - Painting with colloidal silver

- 17 Étape 13 - Step 13 – Production - Packing of filters

- 18 Étape 14 - Step 14 - Use - Maintenance - Replacement

- 19 Étape 15 - Step 15 - Case studies

- 20 Notes et références

- 21 Commentaires

Introduction

In 1990, approximately 2.3 billion people do not have access to drinking water in the world (source: UNICEF - UN). Today in 2020, 750,000 people still drink unsanitary water, making it the leading cause of non-age-related death in the world.

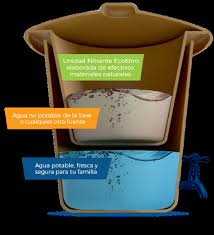

What is a ceramic water filter ?

Locally produced ceramics have been used to filter water for hundreds of years. The water is poured into a porous ceramic filter pot and is collected in another container after passing through the ceramic pot. This system also allows for safe storage until the water is used. Ceramic filters are usually made from clay mixed with a combustible material like sawdust or rice husks. Sometimes colloidal silver is added to the clay mixture before firing or it is applied to the fired ceramic pot. Colloidal silver is an antibacterial which helps inctivatae pathogens, while preventing the growth of bacteria in the filter itself.

How does this filter remove contamination ?

How does it remove contamination?

Pathogens and suspended elements are removed from water by physical processes such as mechanical entrapment and adsorption. Quality control regarding the size of the combustible materials used in the clay mixture ensures that the pore size of the filter is small enough to prevent contaminants from passing through the filter. Colloidal silver facilitates the treatment by breaking the membrane of the cells of pathogens, causing their death. History

Historique

History

This filter was developed in 1981 by Dr Fernando Mazariegos of the Industrial Research Institute of Central America (ICAITI) in Guatemala. The aim was to make water contaminated with bacteria safe for the poorest by developing an inexpensive filter that could be manufactured at community level. The professor decided to freely bequeath this knowledge to Humanity, and began to train potters around the world to produce these filters locally with the NGO Potters for Peace. There are now 61 factories working with this model in 39 countries around the world!

This tutorial show how the ceramic filter works and outlines the main stages of manufacturing. It is aimed mainly at entrepreneurs rather than at individuals. Don’t try to create this technology at home (you need an oven, you need to test materials, etc.). If you are interested in setting up a small factory like this, you will need more training. The Potters for Peace organization in partnership with CAWST and the company Ecofiltro (which we visited in Guatemala) offer this kind of training. All this knowledge is freely available in open-source form.

Youtube

Matériaux

- Materials

- Sawdust

- Clay

- Clean water: for mixing with the clay and the flow tests colloidal silver

- Container with tap (ceramic, plastic, metal)

- Plastic bags for the pressing process

- Fuel for the oven

Outils

- Balance

- Mixer: to mix clay, sawdust and water

- Extruder: to extrude the clay mixture into blocks for moulding

- Hydraulic press equipped with male and female moulds

- Drying shelves: to dry the pots before firing.

- Ovens: for the ceramics

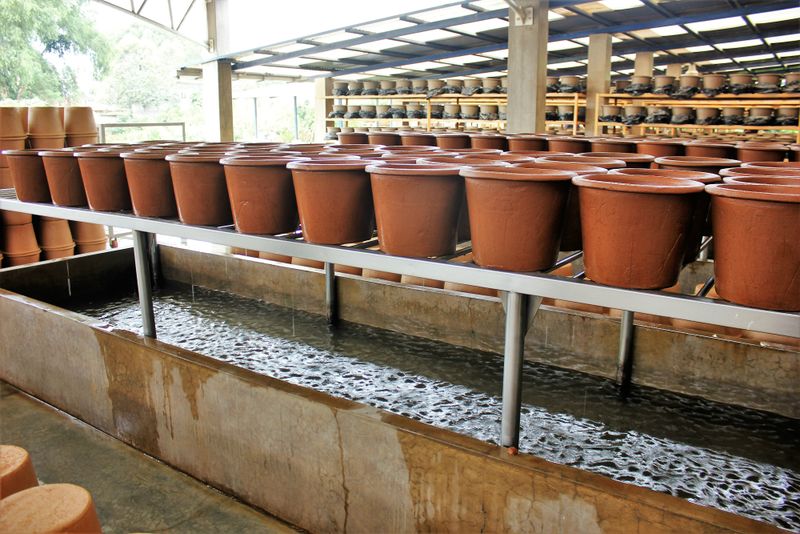

- Basins + Supports: for carrying out the flow tests

Étape 1 - Step 1 – how it works - role of the different materials

- Clay :

Clay is the base material for the water filter device. A clay pot allows for extremely slow movement of water through the natural pores that exist between the fired clay tablets. The size of these pores has been measured (using an electron microscope) and found to be between 0.6 and 3.0 microns (μm).

They are able to eliminate most bacteria, protozoa and helminths (Lantagne, 2001a), as well as dirt or sediment and organic matter.

The clay used to make classical pottery may be suitable for the production of water filters. However, hydraulic conductivity and pore size can vary widely depending on the type of clay, potentially to the point of not being suitable for flow rates and / or microbiological removal (Oyanedel-Craver and Smith, 2008, in Lantagne et al, 2010, [1]). A high content of sand or silt in the clay can reduce cross-linking of the clay and weaken the structure of the filter. On the other hand, an overly refined clay (smaller particles) has a greater water holding capacity and is therefore more prone to shrinkage and cracking during firing.

As the characteristics of clay are a critical factor in the success or failure of ceramic water filter production, it is recommended that you carefully study the sources and potential types of clay before committing significant resources. Potters for Peace has produced a document providing details of the clay test, listed in the "Reference Note" section [18]

- Combustible material :

"Combustible" organic materials, such as sawdust or ground rice husks, are added to the clay mixture. When exposed to the high temperatures of the kiln, the "combustible material" burns, leaving behind cavities in the fired clay. Water moves more easily through cavities than through pores in clay. Therefore, the presence of the cavities decreases the distance that water must travel through the clay substrate, and therefore increases the overall flow rate of the filter.

It is important to carry out tests on your materials. The ratio of clay to combustible material is important for establishing the flow rate and therefore the efficacy of the filters.

- Colloidal silver :

Colloidal silver is a solution made of suspended nanoparticles of silver and silver ions. It has been used as a natural disinfectant in medicine for many years. Although the exact mechanisms of bacterial destruction are not yet fully understood, it appears that colloidal silver breaks down the cell walls of bacteria and then binds to their proteins, thus disrupting their function [2] [3]. Today it is mainly produced by electrolysis.

The silver applied to the inside and outside of the filter is absorbed into the pores of the clay. The silver ions are reduced to elemental silver and form colloids inside the walls of the filter. Silver acts as a biocide against bacteria when there is sufficient contact time (= not too large pores).

Étape 2 - Step 2 – how it works - Efficacy

All the laboratory and field efficacy values are the result of independent trials. The details are given in the links in the "Notes and References" section

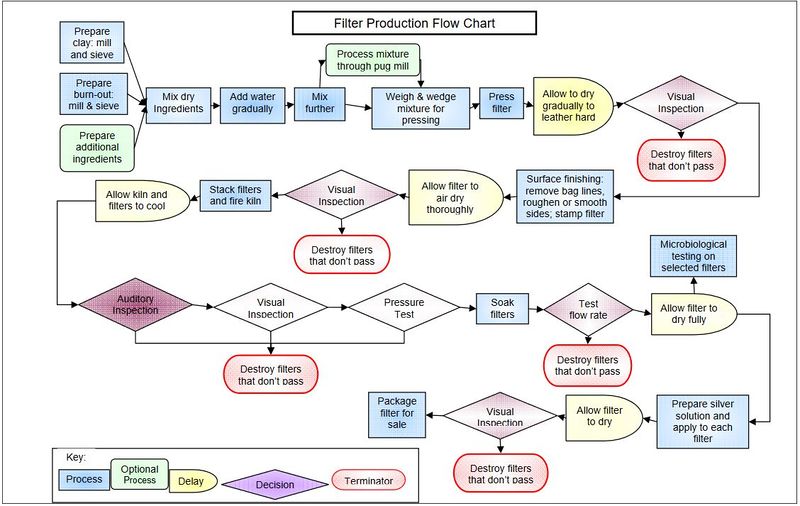

Étape 3 - Step 3 - Production - Summary of steps

The main steps for producing a ceramic filter are listed in order below :

- Prepare of raw materials: clay powder, sawdust / ground rice husks, water

- Mix the raw materials to form a malleable paste: clay powder, sawdust / ground rice husks, water

- Form cubes of clay for the press

- Press the clay cubes to turn them into the filter shap

- Finish the surface and mark / number each filter

- Dry the filters - to remove the initial excess water finish

- Baking the filters in an oven - to complete dehydration and vitrification

- Flow tests for each filter - for validation or downgrading

- Colloidal silver painting on the surfaces of each validated filter

- Package filters

Étape 4 - Step 4 – Production - Preparation of raw materials

- Clay: Depending on its provenance, clay may need to be crushed, sieved and dried before it can be used.

- Combustible material: Depending what it is (sawdust, rice husks, etc.), the combustible material will need to be cut, sieved, dried and bagged.

Étape 5 - Step 5 – Production - Mixing of raw materials

Clay powder and combustible material (sawdust, ground rice husks, etc. ) are mixed dry, then water is added evenly and mixed well to form a modulable and homogeneous paste.

It is wise to make sure density gradient is consistent throughout the clay mixture to minimise potential defects during the clay firing process (removal of air pockets etc.). The right mix and machinery is therefore crucial.

Proportion used by RDIC:

30 kg of clay powder + 8.9 - 10 kg of rice husks + 12.5 L of water

Étape 6 - Step 6 - Production - Forming clay cubes for the press

The wet clay mixture can be manually shaped into cubes before being pressed. But it is strongly advisable to use a machine to compress and extrude the clay mixture as cubes. The extruder is similar to those used for extruding clay bricks, but the outlet opening is larger to obtain the size of clay cube required for pressing.

The clay cubes we want should weigh approximately 8kg.

Cut a cube of the same length and put it in the press.

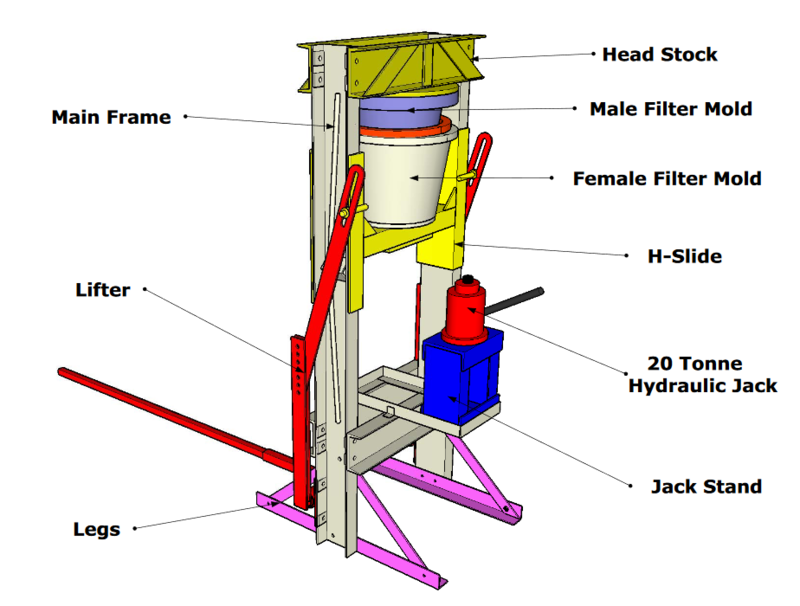

Étape 7 - Step 7 - Production - Pressing the clay cubes to give them the shape of the filter

Using a hydraulic press significantly reduces the labour requirements of the process and greatly increases the efficacy and consistency of the product. The filters are squeezed between a male mould and a female mould which are covered with plastic bags to prevent sticking. The hydraulic press includes a fixed plate in the lower mould that pushes the pressed mould outward when the mould opens.

This press was originally developed and built by the Potters for Peace teams:

Étape 8 - Step 8 - Production - Finishing of the surface and marking/numbering each filter

Minimum surface finishing is required after molding. It is done to ensure rim strength and surface uniformity. Filters are labelled to indicate pressing date, batch and filter number.

- Use a plastic scraper to smooth out the edges of the border.

- Mark each filter with a date, serial number and manufacturer's name using a metal "stamp". A database can then be used for filter tracking

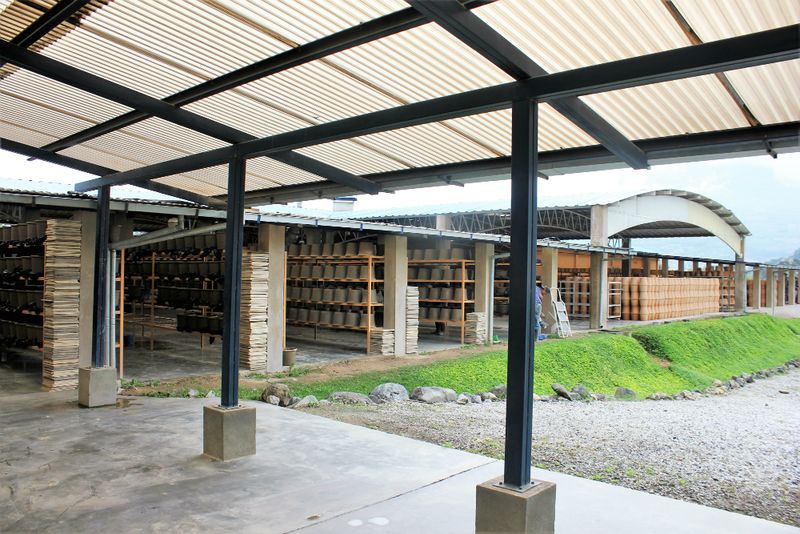

Étape 9 - Step 9 - Production - Drying the filters

Drying the filters eliminates excess water before firing in the oven. If the water is not removed before firing, it will heat up, evaporate and expand, causing the filter to crack. At the end of the firing process, the filter elements will have lost more than 3 kg of water compared to the first time they are pressed.

Dehydration: filters are initially dried on air drying racks. Ideally in a warm place with good ventilation. After this initial drying period, the filters may retain their shape but are not solid and remain soluble in water.

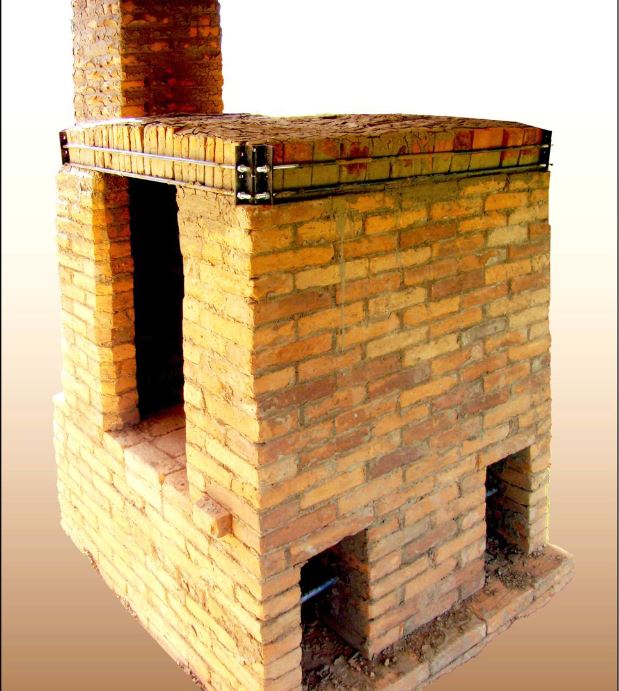

Étape 10 - Step 10 – Production – firing filters in an oven

- The firing process is done initially at a low temperature of around 100ºC for 2 hours. This will remove excess water remaining.

- Finally, the temperature is gradually increased to high temperatures. At 866 ° C, clay vitrifies as the silica and alumina molecules melt and bind to form a new mineral with needle-like fibrous structures. Vitreous clay is hard, resistant to stress and does not change shape when water is added. After vitrification, clay has a new chemical structure and cannot be powdered and reused as clay dust.

- Fire at 900 ° C for 9 hours.

You can use different types of ovens and different types of fuels (wood, gas, etc.). Potters for Peace has created two documents teaching you build a traditional clay oven "Mani Kiln" [20] [21][20] [21]

Étape 11 - Step 11 - Production - Flow testing of each filter

Flow control is an important step in quality assurance which indicates the rate at which water flows through the filter. Once the clay formula and production process has been established, the flow test is performed on EACH filter produced to ensure its viability.

A filter passes the control if its flow rate is within 1.5-3L per hour. Otherwise, it is downgraded and will have to be destroyed.

- A high flow rate is an indicator of cracks or imperfections in the filter which could reduce the efficacy of the filtration and not remove bacteria, parasites and other necessary impurities. In addition, a high flow rate reduces the time the filtered water is exposed to the silver solution, thus reducing the ability to kill bacteria present in the water.

- Too low a flow rate may prove impractical for households who may choose to no longer use the filter and therefore waste their investment and put their health at risk.

- Fill each filter with water and measure the level of water after a set period of time.

Étape 12 - Step 12 - Production - Painting with colloidal silver

Silver is known for its ability to kill microorganisms. Colloidal silver has been used in hospitals and clinics as an antimicrobial agent for cuts, burns and to prevent eye infections in newborns (Lantagne, 2001) and to disinfect drinking water and swimming pools (Russell , 1994, in Lantagne, 2001). The silver is used by NASA to purify water from space flights (NASA CASI, 2007).

- Prepare your colloidal silver solution according to the concentration and shape of your silver.

For example, the RDIC manual describes:

- Add 100 g of AgNO3 crystals (RDIC buys crystalline AgNO3 with a purity of about 99.8%) to 500 ml of deionized water and mix well

- Add 1000 ml of deionized water to the solution and mix for 1 minute.

- Store this concentrated silver solution in a light-resistant plastic container.

- To make the silver solution, take 100 ml of the concentrated silver solution and place it in a light-resistant container. Add 18 litres of distilled water and mix. 18.1 L gives enough solution for about 60 filters. (Note: The containers should be kept closed because the silver in the solution oxidizes when exposed to air.)

- ~ 47 mg or about 200 ml of solution is applied inside the filter to the using a brush.

- ~ 23 mg or 100 ml of solution is applied to the outside of the filter

- Allow the filters to dry for a few hours.

Étape 13 - Step 13 – Production - Packing of filters

Each filter must go with a container fitted with a tap. The containers may be made of different materials (plastic, ceramic, glass, stainless steel). Make sure when packaging that the contents of the cardboard box will be protected during transport.

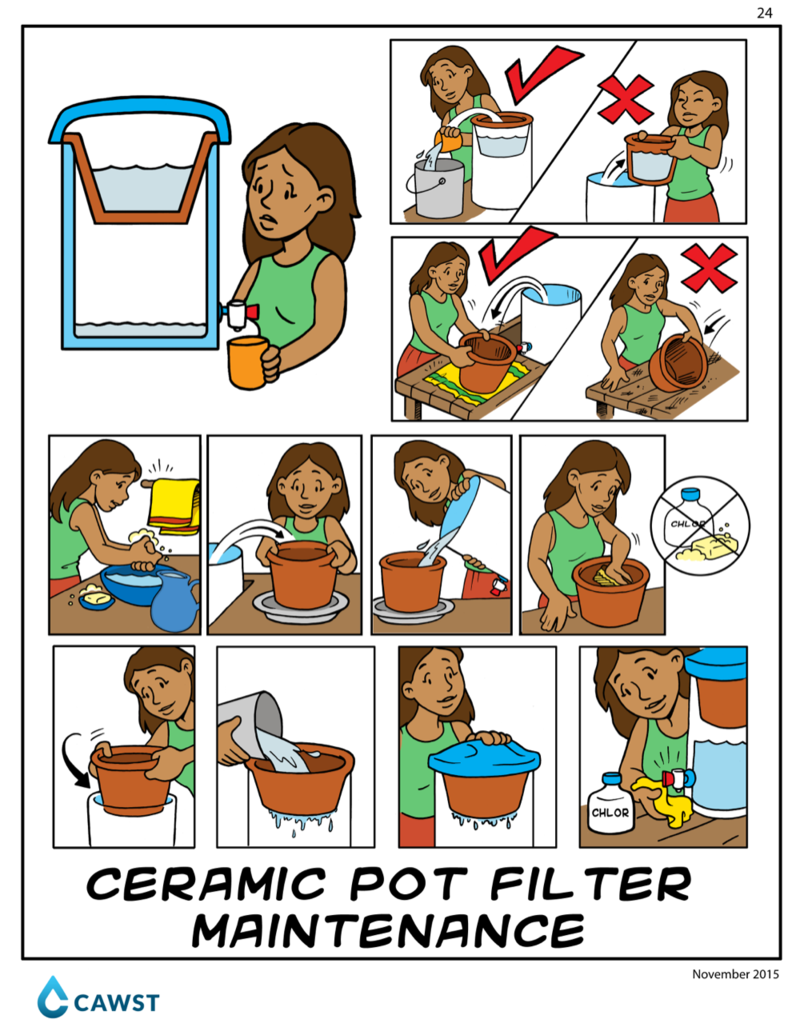

Étape 14 - Step 14 - Use - Maintenance - Replacement

It is important to distribute these filters with good instruction leaflets on how to use, maintain and replace the filters.

- Operation and maintenance: the user pours water into the filter. The water moves slowly through the ceramic pot by gravity; it is then collected in a hygienic storage tank. Users have access to the treated water via a tap.

- Maintenance: the lower tank, tap and cover should be cleaned regularly. The ceramic pot should be cleaned every 6 months with a cloth or soft brush, taking care not to touch the bottom of the pot with anything that may be contaminated.

- Replacement: Ceramic pots should be replaced every 2-3 years, or sooner if visible cracks appear.

Étape 15 - Step 15 - Case studies

If you are interested in this technology and wish to learn more about how to set up a factory locally, have a look at these case studies proposed by the CAWST:

- Implementation Case Study: Ceramic Pot Filters, Cambodia

- Implementation Case Study: Ceramic Pot Filters, Myanmar

- Ceramic Pot Filter Production China: JiaRun

Notes et références

Notes and references This tutorial was written by Guénolé Conrad following the visit of the Ecofiltro factory in Guatemala in November 2020, which was a stopover on the Nomade des Mers expedition.

This tutorial is largely based on the open-source documentation provided by RDIC, CAWST and Potters for Peace. Some photos from these tutorials have been used.

----

1. Lantagne, D., Klarman, M., Mayer, A., Preston, K., Napotnik, J., Jellison, K. (2010). Effect of production variables on microbiological removal in locally-produced ceramic filters for houshold water treatment. International Journal of environment Health Research.

2. Latagne, D. (2001) Investigation of the Potters for Peace Colloidal Silver Impregnated Ceramic Filter

Translations:Filtre à eau céramique/80/en 3. Effet de l'argent colloidal comme désinfectant: Ehdaie Beeta, Su Yi-Hsuan, Swami Nathan S., Smith James A., ; (2020) Protozoa and Virus Disinfection by Silver- and Copper-Embedded Ceramic Tablets for Water Purification

9. Long-term evaluation of the performance of four point-of-use water filters.

10. Removal of virus to protozoan sized particles in point-of-use ceramic water filters.

13. Virus removal efficiency of Cambodian ceramic pot water purifiers.

18. Potters For Peace ; Clay Testing Protocol for Ceramic Water Filters

19. Potters for Peace ; Plans for a Filter Press

20. Potters for Peace; How to build a Mani Kiln

21. Potters for Peace; Air flow of a Mani Kiln

Published

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português